7X YOUR BUSINESS WITH VERTIDRIVE

Ready to multiply your productivity and get back into action faster? With VertiDrive’s advanced robotic solutions, you can achieve up to 7x

quicker surface preparation on large steel surfaces, freeing up more time to take on new projects, reduce downtime, and maximise efficiency.

Say goodbye to delays, excessive labour, and hazardous work environments. VertiDrive delivers precision, safety, and speed, so your business can move forward without limits. Elevate your operations, accelerate your workflow, and watch your business soar.

01

Faster

VertiDrive robots significantly increase productivity by semi-automating surface preparation processes that traditionally take longer with manual methods.

02

Safer

Prioritise safety by reducing human exposure to heights as well as hazardous environments and high-pressure equipment.

03

Cleaner

VertiDrive technology has options built to be environmentally responsible, minimising waste and reducing the environmental footprint.

04

More Profitable

Reduce overall project costs through labour savings, material efficiency, and faster project turnaround.

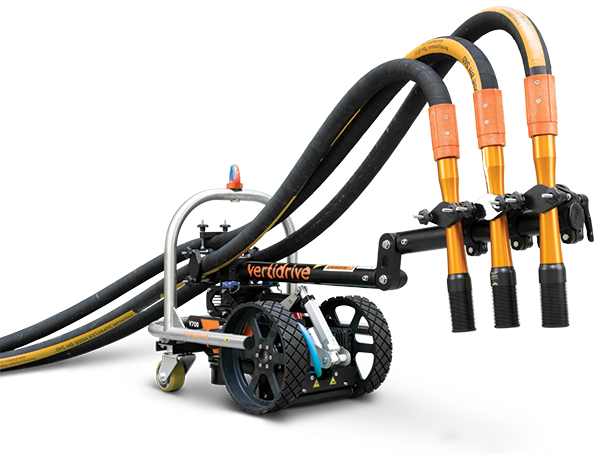

INTRODUCING THE V700 AND V400

V700

A Multi-Functional robot for surface preparation, offering:

- Abrasive blasting for coating removal.

- High-pressure washing for cleaning.

- Ultra-high-pressure (UHP) blasting for tough coatings.

- ATEX version available.

V400

An Ultra-High Pressure (UHP) robot for surface preparation, offering:

- Ultra-high-pressure (UHP) blasting for tough coatings.

- High-pressure washing for cleaning.

- Closed-circuit system available, meaning no waste is released into the environment.

- ATEX version available.

REQUEST PRICING OR A LIVE DEMONSTRATION

We’ll discuss your project requirements and the suitable VertiDrive to multiply your productivity and get back into action faster!

Efficiency and Productivity

Up to 7x faster than manual blasting! VertiDrive speeds up large-scale surface preparation by using up to three (3) #8 blast nozzles with the V700. Reduce project time and allow assets to return to service quicker.

Precision and Consistency

Achieve a consistent blast profile by automating timing and speed of your blast. Automated parameters (e.g., blast width, nozzle speed) guarantee precision. Eliminate human error and irregularities in surface preparation.

Increases Safety and Reduces Risk

Remote-controlled operation significantly reduces the need for workers to operate in dangerous conditions. Less scaffolding required, reducing fall risks and other worksite hazards. Minimise worker fatigue as most of the labour is automated.

Cost Savings

Minimise reliance on large teams of manual blasters and reallocate skilled labour to other critical areas of the project. Minimise abrasive and water waste through precise, metered blasting. Less downtime and shorter project durations means overall project cost reduction.

Environmental Considerations

V400 robots can operate in closed-circuit setups, capturing waste and preventing environmental contamination, such as paint going into waterways. Ultra-high pressure (UHP) systems minimise abrasive waste, reducing air and site pollution.

The Forefront of Robotic Solutions

VertiDrive technology paired with BlastOne’s extensive equipment and material expertise, sets a new standard for industry performance. This powerful combination is already driving success in projects across marine, oil & gas and heavy industrial sectors.

Discover the Benefits of the VertiDrive

The Downloads You Need on VertiDrive – Get Them Here

Is the Vertidrive right for my project?

The following are key indicators in determining whether the Vertidrive is a solution for your project.

-

Project Size – due to the rental cost and one week minimum, renting the Vertidrive becomes cost effective on projects 10,000 ft2 and greater.

-

We recommend a 1600 cfm compressor to utilise a 3-nozzle set-up.

-

As the robot adheres to the wall via a magnet, the substrate needs to be steel, with a plate thickness of 3/8″ minimum. 1/4″ steel is not recommended.

-

Being magnetic, you cannot use steel grit or shot with the VertiDrive. It will quickly coat the magnet and eventually cause it to dislodge from the surface.

-

Storage Tanks need a minimum 15ft diameter to allow the robot to run sideways.

Valuable Considerations

-

The Vertidrive will typically blast approximately 85%-90% of a storage tank. Hand blasting will still be required to touch up difficult areas, stairs, rails, or welds possibly under-blasted due to the angle of the nozzles.

-

The Vertidrive can effectively traverse welds or plate laps up to 5/8″ high. Anything greater can cause the robot to detach from the surface.

-

The Vertridrive is safe-guarded on vertical surfaces by a safety retractable line. It requires 3 SRL’s to operate upside down on the underside of a floating roof tank or bottom of a ship.

Case Studies

Related Videos

Sandblasting Upside Down On Ship

BlastOne VertiDrive Blasting Robot

VertiDrive for High Pressure Cleaning

Opimising Productivity

Frequently Asked Questions

Do you offer jobsite demonstrations?

Due to supply and demand and the freight cost of shipping the robot with its container, this is typically not possible. We invite all those interested to attend our next Demo Day where we exhibit all the latest and greatest blasting innovations and can let your team get hands on the equipment and see it in action. Here is the link to our Technology Day info and calendar.What size compressor do I need?

We recommend a 1600 cfm to fully utilize all three nozzles. Smaller compressors can work, however we cannot guarantee production numbers.

Do you offer training with rental/purchase?

Yes. For first time rentals or purchase we provide training. This is a two (2) day hands-on training which covers the requisite set-up needed to achieve the production outputs. We cover the VertiDrive, blasting equipment, compressors, and air dryers. During this time, the tech support doesn’t run the robot, but oversees your team handling the controls. They are taught how to blast, start, stop, and basic trouble-shooting.

There is a fee for this training. Estimate between $5,000 – $7,500.

Can the robot blast upside down?

Yes. The VertiDrive can blast vertically, horizontally, and even upside down.How does the robot adhere to the surface?

The robot has 2 strong magnets on the underside carriage. These are earth magnets – not powered by electricity. Therefore, should you lose power to the jobsite, the robot will not detach from the wall.Is this hung by a cable?

No, it uses a safety retractable line, to protect it from falling.You can use a winch system to hold the hoses when you are blasting over 40ft high.

What happens if the robot detaches from the wall while blasting?

The robot has a proximity switch monitoring its distance from the surface… so if it comes loose, the system will shut down, preventing the nozzles from indiscriminately blasting abrasive should it swing or fall.The robot also needs to have a tie-off point, like a clamp – utilizing a safety retractable line, positioned no greater than thirty (30) feet from the working area. As the robot cleans the surface and moves to the next work area, this tie-off point should be adjusted accordingly. This distance is a safety measure and prevents the robot from swinging like a wild pendulum should it detach from the wall.

Can it drive over patches and overlaps?

The machine will drive over 5/8″ welds or laps. Greater heights can affect both the proximity sensor and magnetic adhesion.How many operators does it take to run the robot?

One worker can monitor and operate the blasting robot, we would typically recommend having another person onsite to be with the blasting equipment to ensure that all 3 nozzles stay supplied with abrasive and free airflow while blasting.You will always need to do some manual blasting, so if your bulk bot has 4 outlets you can always keep another busy doing the cutting in.

What is the daily / weekly maintenance involved?

Maintenance on the Vertidrive is very minimal, just keep the magnets clean. There is nothing to lube as it has all-sealed bearings.

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing Air preparation and drying equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account