Conjet Hydrodemolition Robot 327

Sku: RUCJ327

Conjet Hydrodemolition Robot 327

SKU: RUCJ327

- Fully automated via the Conjet ONE control system

- Track extensions for maximum stability

- Track sensors control travel distance

- Arm and feed beam can rotate 360°

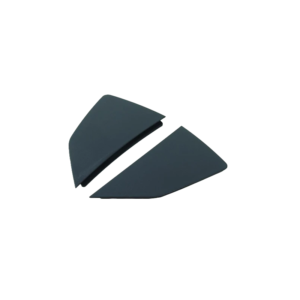

- Removable side-covers enabling optimum reach in corners

- Compact feed-beam

- Accessory kit makes it very flexible and multi-purpose

Read More

Categories: All Products, Concrete Demolition, Site Solutions & Rental

Tags: 327, automated, automatic, concrete, Conjet, demolition, electrically powered, high-pressure, HP, hydrodemolition, nozzle, Remediation, robot, RUCJ327, water

Conjet Hydrodemolition Robot 327

SKU: RUCJ327Web price i

Please sign in to your account to see your pricing, which may be different from the price displayed.

Request Quote

Ship to

Conjet Hydrodemolition Robot 327

Sku: RUCJ327

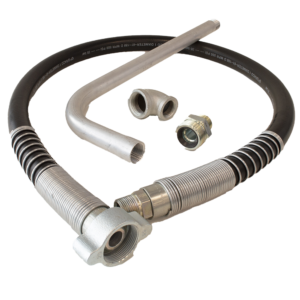

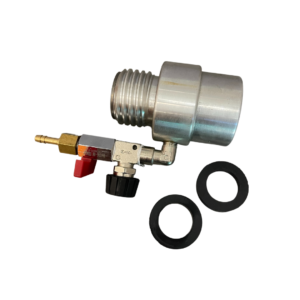

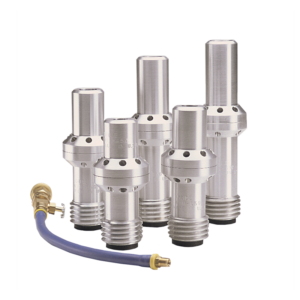

The Conjet Robot 327 is an electrically powered, track-driven, completely automated concrete removal robot that is compatible with the Conjet ONE control system. The robot has been evolved to work in confined spaces and areas. It passes via an opening less than 900mm wide. The Robot 327 is exceedingly customisable. Different versions of tools and arms may be combined to match your project’s requirements. Apart from the arm and tool configurations, the high-pressure lance at the Robot 327 may be fitted with either a single or double nozzle assembly depending at the type of work. The robot also can be equipped with a winch for working on slopes. In addition, a rotary head can be connected for surface preparation. Conjet’s 7-Series ACR™ robots are versatile and reliable. Conjet equipment is safe and faster than manual work, and supports BlastOne’s mission to keep the operator out of harms way. Conjet robotics are: Reliable They use industry leading components which make Conjet’s ACR™ robots built for the harshest environments. In addition, Conjet’s durable ACR™ robots ensure users experience trouble-free operation with minimal unplanned downtime. User Friendly The 7-Series Conjet ACR™ robots are equipped with a remote control unit with color screen, giving operators the opportunity to set and visualise the parameters. Manouverability of the robot is easy for operators robot with the use of two joysticks. In addition, an Intuitive GUI (Graphical User Interface) allows for trouble free programming and monitoring of the hydrodemolition process. Safe The operator can stand and supervise from a safe distance during the hydrodemolition process, controlling both the robot and the pump via Bluetooth communications as if they were ONE unit. It's called Conjet ONE – the safest way to remove concrete. Versatile A 7-Series Conjet ACR™ robot allows users to perform a wide variety of tasks. For example, the unique MPA (Multi-Purpose Arm) on the Robot 557 can be adjusted to various positions and heights by the flick of a switch, which allows users to reposition the cutting head in seconds. There is also a range of accessories to further increase flexibility to meet specific project needs.Related Products

Contact Blastone

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account