BlastOne Holiday Detector

BlastOne Holiday Detector

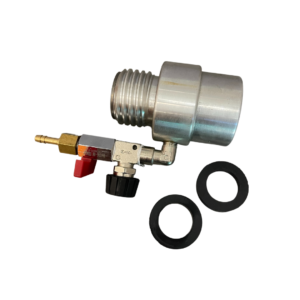

BlastOne PCWI Porosity Detector Holiday Detector Kit.

2 Models available.

Recommended for all coating services, chlorinated rubber and on very thick coatings

Compact pinhole detector design with display showing LED voltage

The Holiday Detector comes with clip-on battery and storage case

When the porosity detector, detects porosity there is a audible and visual alarm

Available in two fully adjustable ranges of voltage – pulse type:

0-15 kV

0-30 kV

Options including fan & flat brushes.

BlastOne Holiday Detector

SKU: IND0606

$6,127.45

$5,570.41 (excludes GST)

Ship to

BlastOne Holiday Detector

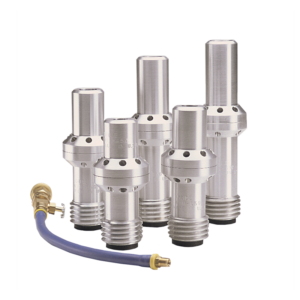

Sku: IND0606

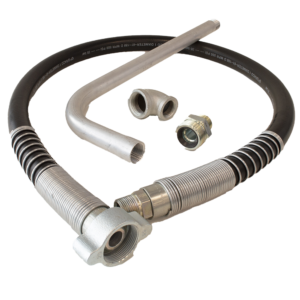

Holiday Detector • Rugged, portable DC output holiday detector with optional 0-15 kV and 0-30 kV models available • Rechargeable overnight, with battery condition and output voltage displayed on LCD • Audible and visual alarm with ‘momentary’ and ‘continuous’ switch functions • Kit includes charger, 78 ½” (2 m) probe, extension, 2 brushes, earth lead, harness, case and certificate Please contact BlastOne for further information What is a holiday detector? What is the difference between a holiday detector and a porosity detector? A holiday detector and a proximity detector are in essence the same thing. An electrical current is run over the painted/coated steel surface and in the event of porosity or pinhole in the coating (also known as a holiday) the current short-circuits to earth and creates an alarm. With high-voltage holiday detectors this can create a spark – hence the name spark tester. BlastOne has complete range of coating inspection instrumentation, such as digital coating thickness gauge, CTG, ferrous or nonferrous, surface profile meters / surface profile measuring device, testex tape, dew point meters, and magnetic surface thermometers. There are many spark tester manufacturers which make different configurations of spark tester/holiday detectors – depending on the application and the complexity of the surface that requires testing for porosity in the paint coating High-voltage spark tester is come with different width bristle brushes or rolling spring probes, which can be used on pipelines Low-voltage sponge detectors and sponge holiday detectors are also available Paint inspectors should use caution when using high voltage porosity detectors high-voltage holiday detector It is important that 100% of the coated surface is tested for pinholes using a spark tester. Where ever a pinhole is located, a repair must be conducted in the paint coating – To ensure long coating life and and low maintenance Most Holiday Detectors have Regulated direct current pulse voltage outputs What voltage should I use for holiday detection/pinhole detection on my paint coating? To determine which voltage I need to use on my spark tester, it is important to refer to the paint coating spec sheet and the relevant standards applicable to high-voltage porosity detection My Account

My Account