Wet Abrasive Blasters

Showing all 5 results

-

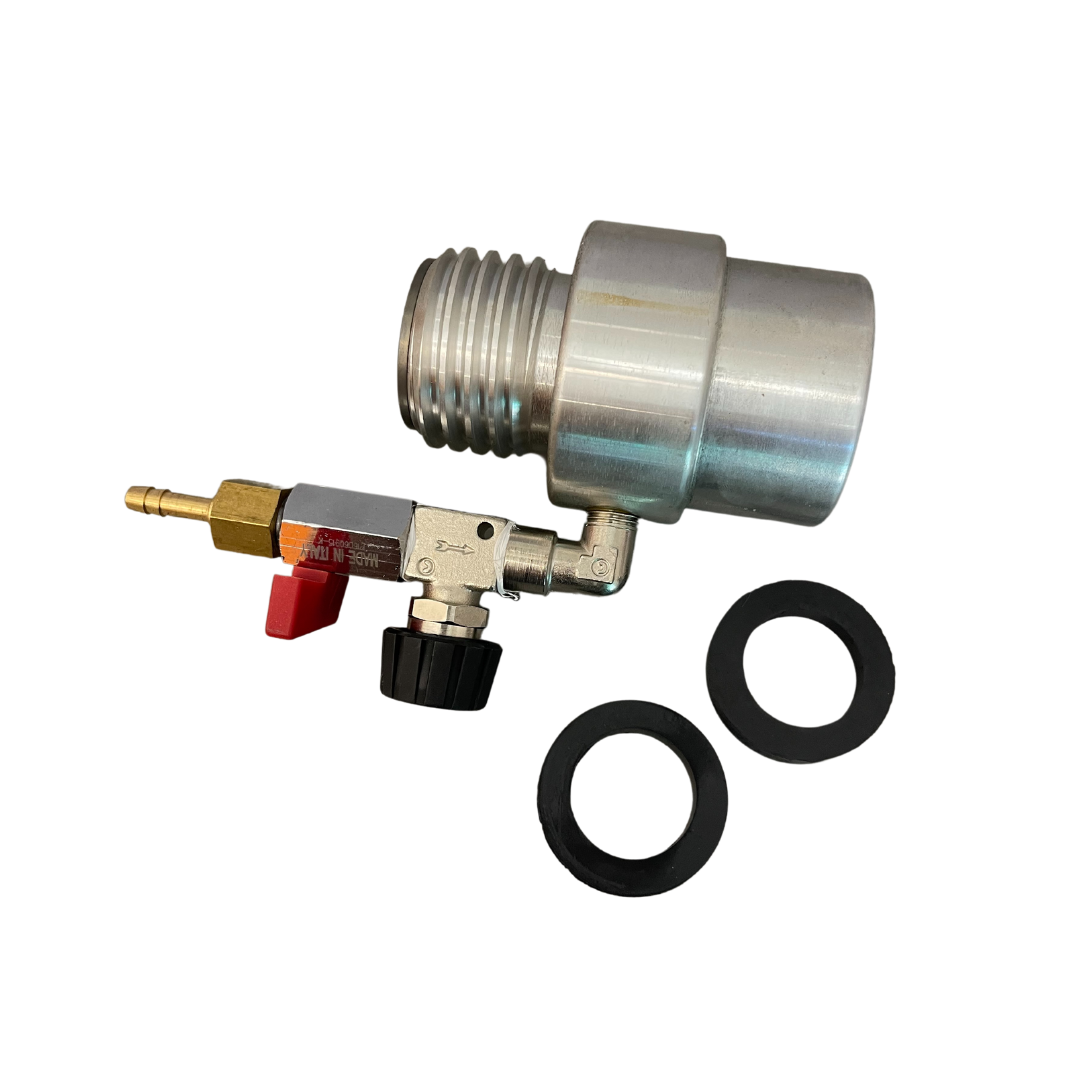

WATER INDUCTION BLAST NOZZLE

- Wet Blast Nozzle

- WIN Nozzle for wet abrasive blasting

- 2" UNC (50mm) coarse Contractor thread

- 1¼" (32 mm) wide throat entry, double venturi

-

BMS65MB-P

The "Mist Blaster For Wet Abrasive Blasting" (SKU: BMS65MB-P) offers a versatile blasting experience with the capability for dustless vapor or dry, washdown, and blowdown. Featuring a pot capacity of 6.5 cu ft and a blast pressure range of 75-150 psi, it's an efficient solution for both wet and dry blasting needs.

- Versatile capability - Dustless Vapor or Dry, Washdown and Blowdown

- Pot capacity 6.5 cu ft / 184 litres

- Blast pressure ranging from 75-150 psi

- Single Outlet with Tera Valve XL metering valve

- Has secondary wheels to ease transportation

BMS65MB-PThe "Mist Blaster For Wet Abrasive Blasting" (SKU: BMS65MB-P) offers a versatile blasting experience with the capability for dustless vapor or dry, washdown, and blowdown. Featuring a pot capacity of 6.5 cu ft and a blast pressure range of 75-150 psi, it's an efficient solution for both wet and dry blasting needs.

- Versatile capability - Dustless Vapor or Dry, Washdown and Blowdown

- Pot capacity 6.5 cu ft / 184 litres

- Blast pressure ranging from 75-150 psi

- Single Outlet with Tera Valve XL metering valve

- Has secondary wheels to ease transportation

-

FOR RENTAL OR PURCHASE

- Combination Skid - MistBlaster and AirDryer Package

- Capable of doing wet and dry blasting - ultimate flexibility for any job!

- 6.5 cu. ft. Schmidt Blast Pot with MistBlaster Conversion

- Teravalve XL Abrasive Metering Valve

- 400cfm Moisture Removal System (Select Deliquescent Air Dryer or Squat AfterCooler)

- 189 liter water tank & pump

- Select if you do or don't want the Operator Accessories Kit (RPB Breathing air filter and GX4 CO Monitor, 5cm Bull hose, 3.175cm SupaFlex Blast Hose, Nova 3 Blast Helmet, and #6 Blast Nozzle)

-

- Wet blast or dry blast with a single unit

- Minimal water usage (less than 1 pint / ½ litre per minute) with proprietary Schmidt M.I.S.T.™ technology that allows precise control of the amount of water injected into the air stream while blasting

- Set and forget switching between machine modes

- Abrasive tank is “dry” so there is no need to drain water to refill with abrasive. This creates a significantly cleaner job site and is more efficient

- Industry-leading productivity and reliability from Schmidt abrasive blasting technology

- Schmidt Tera Valve™ XL abrasive metering valve offers precise and repeatable control of a wide range of coarse or fine abrasives

- Wide range of blasting pressure capabilities from 10 to 150 psi

- Toggle between wet blast, dry blast, and blow-off using a single control panel

- Increased portability

My Account

My Account