Blasting

Showing 376–390 of 628 results

-

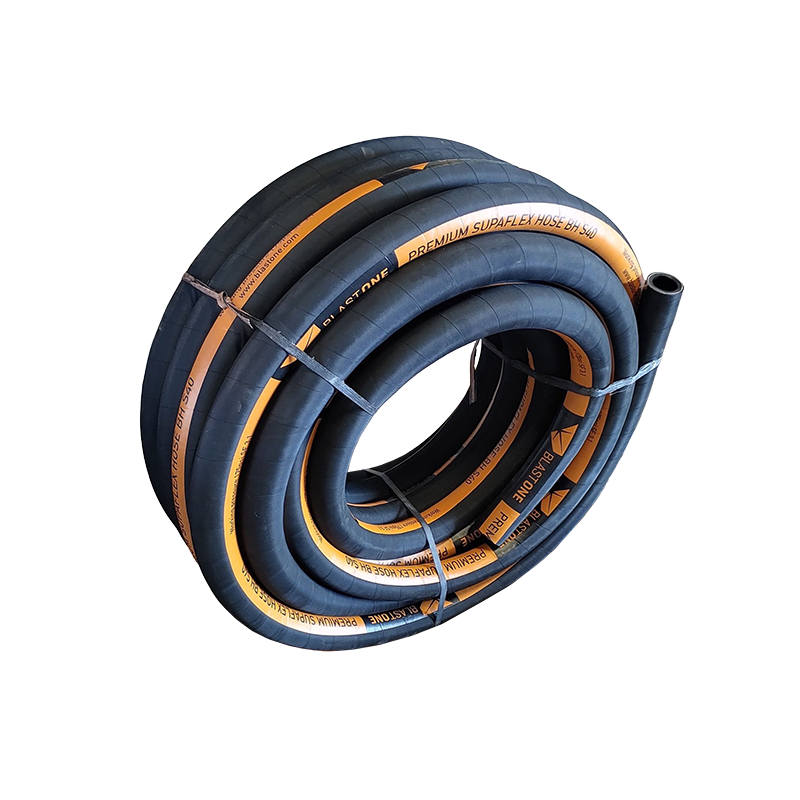

BlastOne's Unfitted Blast Hose – Whip SupaFlex 2ply is a premium sandblasting hose engineered for professionals who demand exceptional performance and flexibility in their blasting equipment. This top-performing hose is designed specifically for contractors and industrial operators who require lightweight, flexible, and durable equipment. Manufactured to BlastOne's stringent specifications, the SupaFlex hose excels in precision blasting tasks, particularly when used as a whip hose in shorter setups or for navigating tight spaces.

Key Features:

- Lightweight and highly flexible whip hose for ease of maneuverability.

- Anti-static natural rubber liner with carbon black for static dissipation.

- Rated to a minimum of 175 psi with a 3:1 safety factor.

- Durable TuffRap™ outer cover for enhanced wear resistance.

- Compatible with a variety of nozzle holders and couplings for custom setups.

- Commonly referred to as whip hose, supa hose, or supahose.

- Available for rental or purchase; request rental pricing as needed.

-

AVAILABLE FOR RENTAL OR PURCHASE- #1 Nozzle Mounted Blast Light Preferred by Blasting Contractors

- Has 6 LED's giving 1,325 lumens light output blast light

- Voltage range - 120 v AC or 12-28 v AC/DC

- Long lasting - the LED blast light lamps will last 20x the life of a halogen globe

- Can be hose mounted or hand-held

- Lights can be repaired but require sending them to factory

-

AVAILABLE FOR RENTAL OR PURCHASE

With Western Technology's impressive Kick-it-tough design, the Brick Light is built to withstand shocks and breakage like no other area light can handle! Other featured highlights as follows:

- Explosion proof light head for use in hazardous locations. Fully explosion proof systems with rated plug and power box are available (C models) or save cost with the A model ordinary location power box and plug when the power box can be positioned outside the hazardous area.

- Brilliant 11,500 lumen 6000K daylight light color for large area-light coverage.

- Highly Flexible with many mounting options and multi-light configurations available, as well as various lengths of cable. Optional dimmer switch available too.

- Coming soon - Easier Serviceability - the Gen3 version has a field-replaceable power cable pigtail/end cap assembly. (Gen 3 has a green pigtail, Gen 1 & 2 versions are black)

-

BNASB15MThe "Jumbo RotorBlast Blast Nozzle 5/16" (SKU: BNASB15M) is a high-quality tungsten carbide nozzle, perfectly designed for RotorBlast internal pipe blasting with a 5/16" (8.0mm) orifice and medium thread.

- Blast Nozzle Jumbo RotorBlast

- Jumbo RotorBlast Blast Nozzle Tungsten Carbide, 5/16" (8.0mm) Orifice, Medium Thread

BNASB15MThe "Jumbo RotorBlast Blast Nozzle 5/16" (SKU: BNASB15M) is a high-quality tungsten carbide nozzle, perfectly designed for RotorBlast internal pipe blasting with a 5/16" (8.0mm) orifice and medium thread.- Blast Nozzle Jumbo RotorBlast

- Jumbo RotorBlast Blast Nozzle Tungsten Carbide, 5/16" (8.0mm) Orifice, Medium Thread

-

BNASB17M

- Blast Nozzle Jumbo RotorBlast

- Jumbo RotorBlast Blast Nozzle Tungsten Carbide, 3/8" (9.5mm) Orifice, Medium Thread

BNASB17M- Blast Nozzle Jumbo RotorBlast

- Jumbo RotorBlast Blast Nozzle Tungsten Carbide, 3/8" (9.5mm) Orifice, Medium Thread

-

BMS10The “Mitey-Mite 1.0 cuft Blast Machine” (SKU: BMS10) offers efficient and reliable spot blasting, packed in a compact size. With a 70 kg Garnet capacity and micro valve metering, it's perfect for touch-ups.

- Smallest production style pot available

- The 1.0 cuft capacity will hold 70 kg of Garnet

- Ideal for in-plant or onsite touch up work

- Comes with Micro Valve Metering Valve

- Comes with moisture trap

- Lid and Screen set sold separately

- 1" Piping

BMS10The “Mitey-Mite 1.0 cuft Blast Machine” (SKU: BMS10) offers efficient and reliable spot blasting, packed in a compact size. With a 70 kg Garnet capacity and micro valve metering, it's perfect for touch-ups.- Smallest production style pot available

- The 1.0 cuft capacity will hold 70 kg of Garnet

- Ideal for in-plant or onsite touch up work

- Comes with Micro Valve Metering Valve

- Comes with moisture trap

- Lid and Screen set sold separately

- 1" Piping

-

BMS20

- 2.0 cuft capacity will hold 140 kg of Garnet

- Ideal for small shops or occasional blasting

- Comes with Micro Valve Metering Valve

- Comes with moisture trap

- 1" Piping

BMS20- 2.0 cuft capacity will hold 140 kg of Garnet

- Ideal for small shops or occasional blasting

- Comes with Micro Valve Metering Valve

- Comes with moisture trap

- 1" Piping

-

- Manufactured by Schmidt Abrasive Blasting & Axxiom Manufacturing to BlastOne specifications

- Valving system designed to have a maximum of 3psi pressure drop

- Specified Capacity (approx)

- 3.5 cu ft / 99 litres

- Abrasive Capacity (approx)

- Garnet - 230 kg

- Steel Grit - 390 kg

- Pressure Rating: 150psi

- Includes: Moisture separator and inlet fitting

-

- Wet blast or dry blast with a single unit

- Minimal water usage (less than 1 pint / ½ litre per minute) with proprietary Schmidt M.I.S.T.™ technology that allows precise control of the amount of water injected into the air stream while blasting

- Set and forget switching between machine modes

- Abrasive tank is “dry” so there is no need to drain water to refill with abrasive. This creates a significantly cleaner job site and is more efficient

- Industry-leading productivity and reliability from Schmidt abrasive blasting technology

- Schmidt Tera Valve™ XL abrasive metering valve offers precise and repeatable control of a wide range of coarse or fine abrasives

- Wide range of blasting pressure capabilities from 10 to 150 psi

- Toggle between wet blast, dry blast, and blow-off using a single control panel

- Increased portability

-

- The most versatile, easy-to-regulate dry blast machine on the market

- 10-150psi blasting pressure range

- With a load skid combined with an inlet filter, this product uses a differential pressure gauge to allow accurate "metering" of hard-to-flow abrasives like Soda and fine Garnets

- With regulators for the blast and tank pressure for accurate control, this product can be used with most abrasive types - fine to coarse

- With the addition of a media vibrator to improve light media flow and an easy-to-use media shut-off valve this unit is perfect for graffiti removal and all other types of soda blasting

- G2 pneumatic deadman control, 55' twinline control hose, 55' water line with wet blast attachment for dust suppression included with purchase

- Genuine Products - Manufactured by Axxiom Manufacturing - Schmidt®

-

NK9010

- Alcohol wipes to clean and sanitize the mask face piece

- Type: Box

- Pack: 5

NK9010- Alcohol wipes to clean and sanitize the mask face piece

- Type: Box

- Pack: 5

-

VAVacuInt55

- Capacity of 4 tons of garnet

- Designed to sit between the VacuLoad and the vacuum head

- Separates abrasive and 90% of dust for reuse or disposal

- Available in 3 sizes – 20, 55, and 100 cu.ft

- Acts as a cyclone separator using power from the main vacuum unit

- No need for compressed air or electric power

- Ideal for abrasive storage

VAVacuInt55- Capacity of 4 tons of garnet

- Designed to sit between the VacuLoad and the vacuum head

- Separates abrasive and 90% of dust for reuse or disposal

- Available in 3 sizes – 20, 55, and 100 cu.ft

- Acts as a cyclone separator using power from the main vacuum unit

- No need for compressed air or electric power

- Ideal for abrasive storage

-

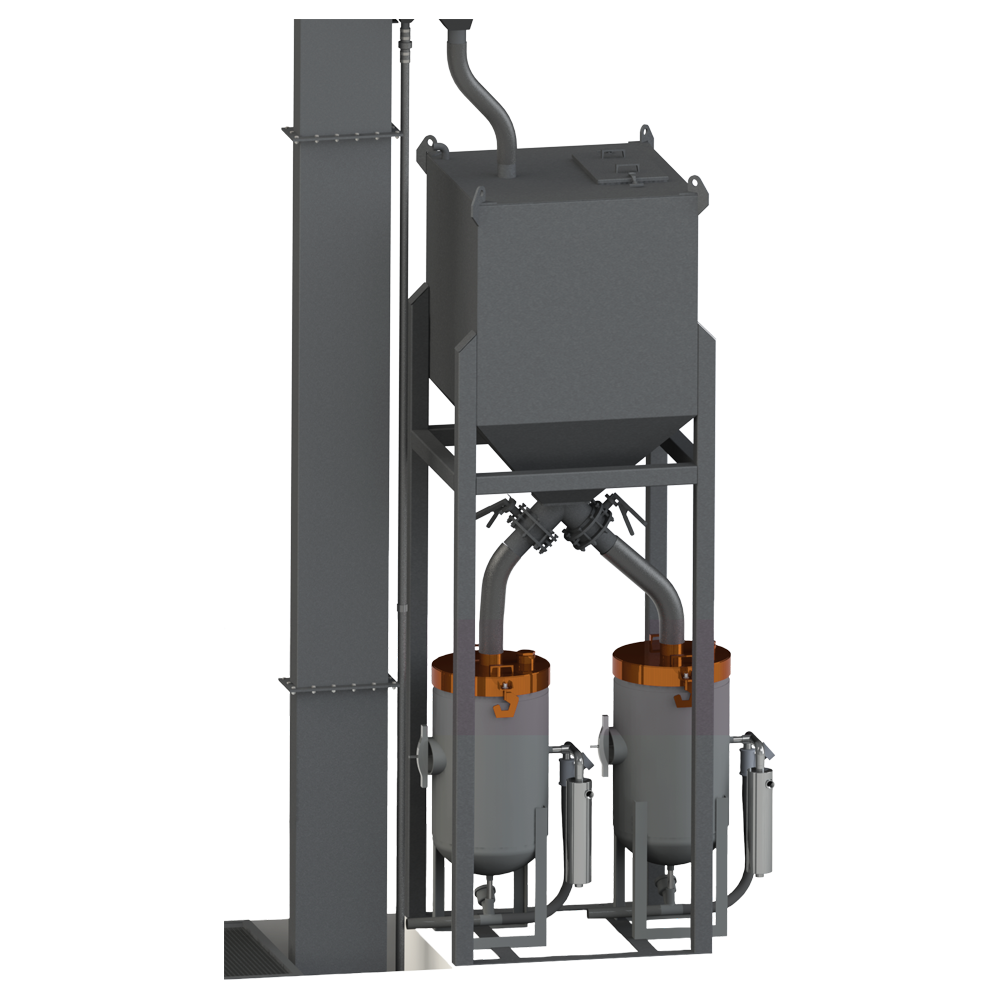

BMS752TVBULK BLAST POT

- Blast Bulk Pot capacity 75 cu ft / 2100 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 5 tonne Bulk Blaster

- Ideal for mounting to the back of a truck

- Comes with 2 Thompson Valve abrasive metering valves, can have upto 4

- Skid Mounted Mega Pot

BMS752TVBULK BLAST POT- Blast Bulk Pot capacity 75 cu ft / 2100 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 5 tonne Bulk Blaster

- Ideal for mounting to the back of a truck

- Comes with 2 Thompson Valve abrasive metering valves, can have upto 4

- Skid Mounted Mega Pot

My Account

My Account