Blasting

Showing 226–240 of 628 results

-

DMBB450000005PKWhen your BAABS Deadman system needs refreshed, we have the replacement parts you need. This is a 3-pack of the Locking Knob w/bolt. Other individual components are also available. See the Repair Parts tab on the main BAABS page here.DMBB450000005PKWhen your BAABS Deadman system needs refreshed, we have the replacement parts you need. This is a 3-pack of the Locking Knob w/bolt. Other individual components are also available. See the Repair Parts tab on the main BAABS page here.

-

APCMF5500Calibration Kit includes:

- calibration tool

- regulator

- Zero Gas

- 5ppm calibration gas

- connector

- tubing

APCMF5500Calibration Kit includes:- calibration tool

- regulator

- Zero Gas

- 5ppm calibration gas

- connector

- tubing

-

The BAABS deadman assembly works on all sizes of blast hose. To facilitate the various hose diameters, a hose adapter set is required. Each adapter set includes 2 grippers (2 sets are used per BAABS) and is offered in the following sizes:

- M1, for HE1 nozzle holder (25mm whip OR 19mm 4-ply hose)

- M2, for HE2 nozzle holder (31.75mm whip OR 25mm 4-ply hose)

- M3, for HE3 nozzle holder (38mm whip OR 31.75mm 4-ply hose)

- M4, for HE4 nozzle holder (38mm 4-ply hose)

-

The industry-proven Schmidt TeraValve™ XL metering valve is revolutionary in its ability to provide high performance abrasive metering while boasting an enhanced service life.

- Durable. The XL (extended life) technology offers more durability - even when blasting with aggressive media like aluminum oxide or steel grit.

- Convenient. No special modifications are required to swap an older pressure-hold valve (like the Thompson) to a Tera. Even older pressure-release pots can be upgraded with a TeraValve Retrofit Kit, as long as there is at least 6" clearance from the bottom of the pot.

- Preferred. BlastOne provides the Tera Valve as standard equipment on all new blast equipment. In addition, we use them in our own rental fleet.

-

SCHMIDT THOMPSON VALVE 2

- Abrasive Metering Valve

- Meters the flow of blasting grit, garnet abrasive sand

- Rugged, simple, bolted construction

- 1 ¼” (32 mm) thread abrasive inlet port

- Features 1” (25 mm) thread side-cleanout port

- Heavy duty tungsten carbide sleeve

- Specify air connection size

- Threaded-plunger metering design with air actuated operation

- The Thompson II Valve uses HF BTC blast coupling – not included (order separately)

- The Thompson Valve 2 is suitable for use with all approved blasting abrasives

- Fit most sand blast hoppers, blast pots or abrasive blasting machines

-

- Pressure-release deadman control valve i.e., blast machine depressurizes when the deadman handle is released.

- Used when an overhead hopper automatically feeds abrasive into a blast machine.

- Rugged stainless steel body, compact, isolated 2-bolt construction.

- Doubles blast machine refill cycle time.

- Virtual Position Indicator illustrates orifice size, giving the ability to set abrasive flow quickly and consistently.

- Set and forget – flow rates stay set where you put them.

- High wear, rugged plunger seal.

- Stainless steel body for long life.

- Improved urethane clean-out port enabling quick removal of obstructions while improving port and valve life.

- Fit a rebuild kit while the valve is still fitted to the blast machine.

- Sold individually.

- Genuine Products – Manufactured by Schmidt / Axxiom Manufacturing

-

- The original Thompson® Valve invented by Bob Schmidt

- Suits a pressure hold system, which retains the pressure in the blast pot, until the deadman handle is depressed

- Meters the flow of blasting grit, garnet abrasive sand

- 3 Nipple size configurations:

- 1 ¼” (32 mm) x 1 ¼” (32 mm)

- 1 ½" (38 mm) x 1 ½" (38 mm)

- 2" (50 mm) x 2" (50 mm)

- Threaded-plunger metering design with air actuated operation

- The Thompson® Valve is suitable for use with all approved blasting abrasives

- Fits most sand blast hoppers, blast pots or abrasive blasting machines

- Genuine Parts - Manufactured by Schmidt® / Axxiom Manufacturing

-

Enhance your blasting efficiency with the Schmidt® MicroValve Abrasive Metering Valve. Designed for precise abrasive flow, this rugged valve ensures optimal sandblasting media use.

- The MicroValve™ changed the industry by providing accurate metering valve

- Most pressure-release Schmidt pots now use the newer MicroValve® 3

- Simple screw type metering through a low-wearing valve

- 1 ¼" (32 mm) thread abrasive inlet port

- Hardened steel threaded base nipple

- Sold Individually, Brass Coupling not included

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

- The MicroValve™ changed the industry by providing accurate metering valve

-

The Schmidt Thompson® Valve II Blast Pot Retrofit Kit converts your existing blast pot into a pressure-hold system, reducing downtime and improving efficiency. Designed for stop/start blasting and multi-outlet blast machines, this OEM Schmidt®/Axxiom kit includes all necessary components for fast-response remote control operation.

Included in the Retrofit Kit:

- Thompson® Valve Series II Metering Valve

- Full pusherline kit

- Automatic air valve with interconnecting hoses

- Control line strainer and control valve

- Response deadman handle and Twinline

- Note: Does not include muffler or pressure relief valve

-

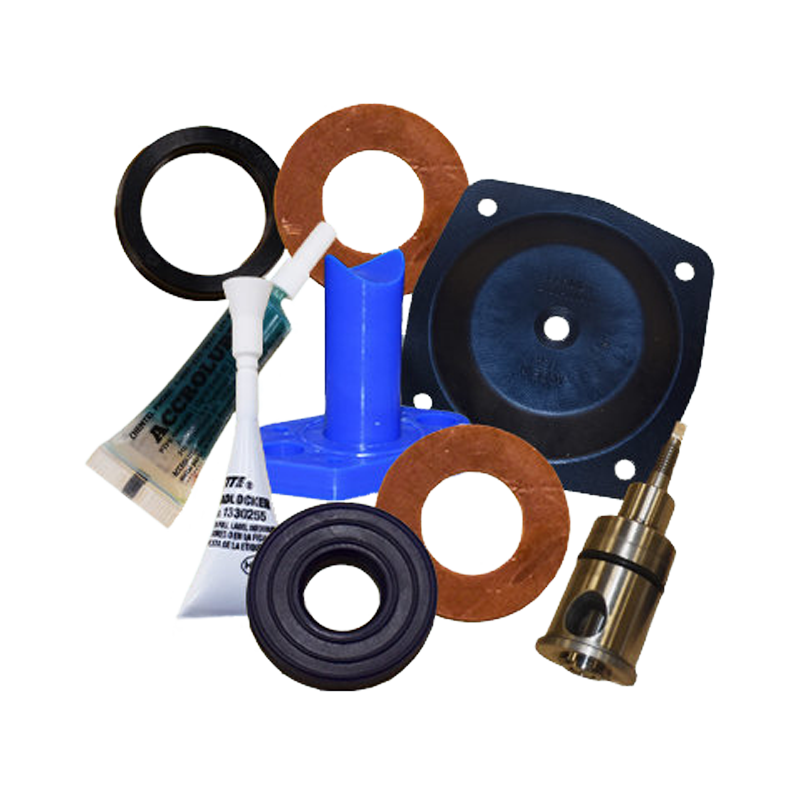

GV212710099

- Repair Kit for MicroValve

- Replacement Repair Kit for MicroValve III

- Schmidt abrasive blasting equipment/ Axxiom Manufacturing part number 2127-100-99

- Complete Rebuild Kit for MicroValve 2 Schmidt / Axxiom part # 2127-100-99 Includes: GV214950006, GV212700005, GV701100506, GV212700012, GV212700015, and GV212710008

GV212710099- Repair Kit for MicroValve

- Replacement Repair Kit for MicroValve III

- Schmidt abrasive blasting equipment/ Axxiom Manufacturing part number 2127-100-99

- Complete Rebuild Kit for MicroValve 2 Schmidt / Axxiom part # 2127-100-99 Includes: GV214950006, GV212700005, GV701100506, GV212700012, GV212700015, and GV212710008

-

GV213000011

- Replacement OEM Body for TeraValve™ XL

- Cast Stainless Steel

- Schmidt® / Axxiom part # 2130-000-11

GV213000011- Replacement OEM Body for TeraValve™ XL

- Cast Stainless Steel

- Schmidt® / Axxiom part # 2130-000-11

-

GV213000099

- OEM Rebuild Kit for TeraValve™ XL

- Includes Tungsten Carbide Sleeve & Plunger along with Seal kit

- Schmidt® / Axxiom part # 2130-000-99

- Includes: GV213000004, GV213000006, GV213000007, GV213000008, GV213000009, GV213000010

GV213000099- OEM Rebuild Kit for TeraValve™ XL

- Includes Tungsten Carbide Sleeve & Plunger along with Seal kit

- Schmidt® / Axxiom part # 2130-000-99

- Includes: GV213000004, GV213000006, GV213000007, GV213000008, GV213000009, GV213000010

-

GV214900099

- Schmidt abrasive blasting equipment / Axxiom Manufacturing part number 2149-000-99

- Repair Kit for Thompson Valve

- Complete Repair kit for Old Style Thompson Valve including the Tungsten Carbide Plunger

GV214900099- Schmidt abrasive blasting equipment / Axxiom Manufacturing part number 2149-000-99

- Repair Kit for Thompson Valve

- Complete Repair kit for Old Style Thompson Valve including the Tungsten Carbide Plunger

-

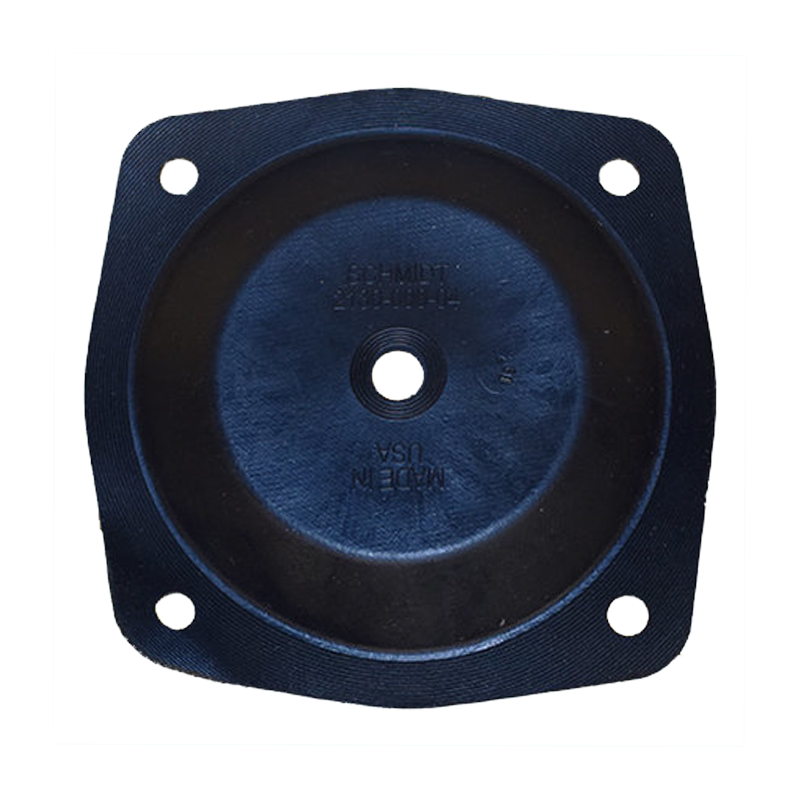

GV213000004

- Replacement Diaphragm for TeraValve™ XL

- Schmidt® / Axxiom part # 2130-000-04

- NOTE - this part is included in the TeraValve Rebuild Kits

GV213000004- Replacement Diaphragm for TeraValve™ XL

- Schmidt® / Axxiom part # 2130-000-04

- NOTE - this part is included in the TeraValve Rebuild Kits

-

GV213000002

- Replacement TeraValve™ XL Cap

- Top part of the TeraValve™, between the Knob and Body

- Schmidt® / Axxiom part # 2130-000-02

GV213000002- Replacement TeraValve™ XL Cap

- Top part of the TeraValve™, between the Knob and Body

- Schmidt® / Axxiom part # 2130-000-02

My Account

My Account