Blast Pots and Machines

Showing 16–23 of 23 results

-

Have a good pot that you hate to throw away? The TeraValve™ Complete Blast Pot Retrofit Kit allows you to obtain state-of-the-art pressure-hold abrasive metering technology and save money in the process! Details as follows:

- Your existing pot must be structurally sound and must have at least 150mm clearance below it.

- The retrofit kit includes a new TeraValve™ as well as all other valves, piping, deadman handle/controls, and hoses required for a complete upgrade.

- Note: Handway and pop-up components are available separately, if needed. In addition, you may want to consider the optional VBS II muffler and/or a union-end ball valve / quick connect (if you have the necessary clearance). See Related Products below.

- Retrofit kits are available in either pneumatic or electric and are offered in both 32mm and 38mm valve sizes.

- Installation instructions are included in the box (and under the Documents tab here). If installation assistance is needed, call us for friendly tech support via phone or we can arrange to have our technicians perform the installation for you.

-

BMS1001TV

- 10.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Single outlet Thompson Valve II abrasive metering valve

- Approx 670 kg garnet abrasive capacity

- Comes with pnuematic deadman handle and 20m of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

BMS1001TV- 10.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Single outlet Thompson Valve II abrasive metering valve

- Approx 670 kg garnet abrasive capacity

- Comes with pnuematic deadman handle and 20m of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

-

BMS200

- 20.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Dual outlet Thompson Valve II abrasive metering valves

- Approx 1350 kg garnet abrasive capacity

- Comes with two pneumatic deadman handles and two lengths of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

BMS200- 20.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Dual outlet Thompson Valve II abrasive metering valves

- Approx 1350 kg garnet abrasive capacity

- Comes with two pneumatic deadman handles and two lengths of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

-

BMS1603TVH1600

- Specified capacity 160 cu ft / 4500 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 23800 lbs / 10.8 tonne

- 1600 cfm Airprep mounted directly on the front of the MegaBlaster Bulk Blaster

- Comes with 2 Thompson Valve metering valves, up to 4 outlets possible

- Skid Mounted Bulk Blast Pot

BMS1603TVH1600- Specified capacity 160 cu ft / 4500 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 23800 lbs / 10.8 tonne

- 1600 cfm Airprep mounted directly on the front of the MegaBlaster Bulk Blaster

- Comes with 2 Thompson Valve metering valves, up to 4 outlets possible

- Skid Mounted Bulk Blast Pot

-

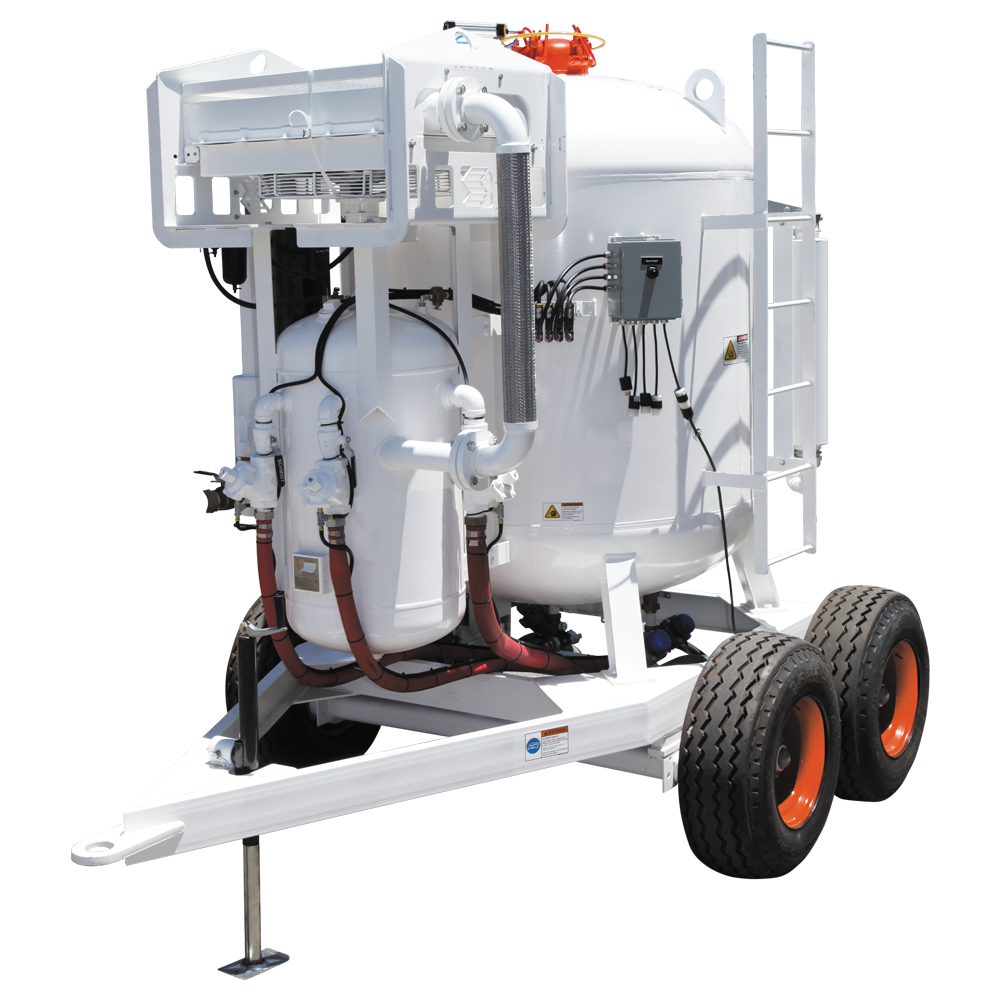

BMS1602TVH1600BULKBLASTER / MEGABLASTER

- Specified capacity 160 cu ft / 4500 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 23800 lbs / 10.8 tonne

- 1600 cfm Airprep mounted directly on the front of the MegaBlaster

- Comes with 2 Thompson Valve metering valves, up to 4 outlets possible

- Skid or Trailer Mounted

- Hybrid Bulk Blaster with built-in Air Drier

BMS1602TVH1600BULKBLASTER / MEGABLASTER- Specified capacity 160 cu ft / 4500 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 23800 lbs / 10.8 tonne

- 1600 cfm Airprep mounted directly on the front of the MegaBlaster

- Comes with 2 Thompson Valve metering valves, up to 4 outlets possible

- Skid or Trailer Mounted

- Hybrid Bulk Blaster with built-in Air Drier

-

RUBVDM2RENT OR PURCHASE THIS VERSATILE, MULTI-PURPOSE SOLUTION!

- Increases productivity up to 300%

- Covers up to 20 m2 / 215 ft2 per hour

- Compatible for use on horizontal, overhead and vertical surfaces

- Closed hydroblasting with vacuum system

- 3X faster than manual blasting

- Blasts an incredible 190 mm (7.5") cleaning width

- Wirelessly controlled - keeps workers out of harm's way

- Strategically designed for quick (dis)assembly

- Pneumatic version available

- No recoil to operator

RUBVDM2RENT OR PURCHASE THIS VERSATILE, MULTI-PURPOSE SOLUTION!- Increases productivity up to 300%

- Covers up to 20 m2 / 215 ft2 per hour

- Compatible for use on horizontal, overhead and vertical surfaces

- Closed hydroblasting with vacuum system

- 3X faster than manual blasting

- Blasts an incredible 190 mm (7.5") cleaning width

- Wirelessly controlled - keeps workers out of harm's way

- Strategically designed for quick (dis)assembly

- Pneumatic version available

- No recoil to operator

-

RUBVDM4CRENT OR PURCHASE THIS VERSATILE, MULTI-PURPOSE SOLUTION!

- Increases productivity up to 800%

- Covers up to 45 m2 / 485 ft2 per hour

- Compatible for use on horizontal and vertical surfaces

- Closed hydroblasting with vacuum system

- 5X faster than manual blasting

- Blasts an incredible 400 mm (15,5") cleaning width

- Wirelessly controlled - keeps workers out of harm's way

- Strategically designed for quick (dis)assembly

- ATEX Zone II, Electric, Pneumatic versions available

- Compact design - fits through 24" manhole

- Convertible to VertiDrive M3 version

RUBVDM4CRENT OR PURCHASE THIS VERSATILE, MULTI-PURPOSE SOLUTION!- Increases productivity up to 800%

- Covers up to 45 m2 / 485 ft2 per hour

- Compatible for use on horizontal and vertical surfaces

- Closed hydroblasting with vacuum system

- 5X faster than manual blasting

- Blasts an incredible 400 mm (15,5") cleaning width

- Wirelessly controlled - keeps workers out of harm's way

- Strategically designed for quick (dis)assembly

- ATEX Zone II, Electric, Pneumatic versions available

- Compact design - fits through 24" manhole

- Convertible to VertiDrive M3 version

-

RUBVDM71

BlastOne's VertiDrive M7 Blasting Robot is an innovative surface preparation powerhouse, engineered to revolutionize large-scale blasting projects. This advanced robotic system, developed exclusively by BlastOne, sets a new benchmark for efficiency, consistency, and safety in industrial surface treatment.

RENT OR PURCHASE THIS VERSATILE, MULTI-PURPOSE BLASTING ROBOT!

- Increases productivity up to 800%

- Blasts up to 60 m2 / 646 ft2 per hour

- Compatible for use on horizontal, overhead and vertical surfaces

- Can operate upside down on steel surfaces via magnets

- Interchangeable applications(washing / hydroblasting / abrasive blasting)

- Does the blasting of 3 blasters

- Blasts incredible 1500 mm / 60" pattern via multi-directional swing arm

- Wirelessly controlled - keeps workers out of harm's way

- Strategically designed for compact working radius

- Powered by robust 70Vdc motors

RUBVDM71BlastOne's VertiDrive M7 Blasting Robot is an innovative surface preparation powerhouse, engineered to revolutionize large-scale blasting projects. This advanced robotic system, developed exclusively by BlastOne, sets a new benchmark for efficiency, consistency, and safety in industrial surface treatment.

RENT OR PURCHASE THIS VERSATILE, MULTI-PURPOSE BLASTING ROBOT!

- Increases productivity up to 800%

- Blasts up to 60 m2 / 646 ft2 per hour

- Compatible for use on horizontal, overhead and vertical surfaces

- Can operate upside down on steel surfaces via magnets

- Interchangeable applications(washing / hydroblasting / abrasive blasting)

- Does the blasting of 3 blasters

- Blasts incredible 1500 mm / 60" pattern via multi-directional swing arm

- Wirelessly controlled - keeps workers out of harm's way

- Strategically designed for compact working radius

- Powered by robust 70Vdc motors

Industry Leading Sandblasting Machines, Blast Equipment & Sand Blast Pots. Australia’s leading abrasive blasting system manufacturer.

Are you needing high performance, superior sandblasting equipment? BlastOne offers a wide variety of blast units ranging from small blast pots to larger bulk blasters and even up to 800 cuft megablasters. Whatever the job, we have the blasting equipment to get it done. Our hand-held Tornado Blaster is a highly effective tool for those needing greater production per blaster, and should interior pipes be an issue for your project, our robotic internal pipe tools come in sizes to fit nearly any diameter pipe.

We are a proud seller of Schmidt blast equipment sandblaster supplies and tools, and each sandblast pot comes with a standard warranty.

Sand Blast Pots

Sizes of sandblast pots available from 1.0 cu.ft to 800 cu.ft – suitable for mineral or steel abrasives.

Portable Sand Blasting Machines

BlastOne is Australia’s leading manufacturer & provider of sand blasting machine. If you are looking for sand blasting machine supplies in Australia, BlastOne is a great partner.

Blast Cleaning Equipment

Abrasive Blast Cleaning Equipment is ideal for remove of paint, rust & scale from steel to provide a clean sand blasted surface profile, to provide a class of blast suitable for new protective coatings. Blast Clean with abrasive creates an anchor pattern to provide excellent coating adhesion & key for coatings to adhere to.

Portable Sand Blaster

A portable sand blast equipment or abrasive blasting unit, is used when moving from job site to jobsite, and the large wheels & maneuverability allows for portability when grit blasting on site, or within a contained blast area. Small portable sandblasting units & equipment can be elevated or taken in lifts up to areas where abrasive blasting & spray painting is occurring.

My Account

My Account