Heavy Duty Sand & Abrasive Blast Nozzles

Showing 31–38 of 38 results

-

VC201831101

- Suits Vacuload Vacuums and Schmidt Eductor

- Nozzle rated to 350 cfm input air

- Long Lasting, if filter is installed before eductor it will last almost forever

- Sold Individually

VC201831101- Suits Vacuload Vacuums and Schmidt Eductor

- Nozzle rated to 350 cfm input air

- Long Lasting, if filter is installed before eductor it will last almost forever

- Sold Individually

-

- Used for blasting pipes 3"-12" Internal Diameter

- Uses tungsten carbide deflection head and 1/2" throat nozzle

- Select the unit that will best match your Air Supply:

- 1/2" Throat Nozzle: 250 cfm

- 5/8" Throat Nozzle: 400 cfm

- Neither of these packages come with a transport carriage - Order Separately

- Collar and Button 3"-5" Pipes

- Scissor Type 5"-12" Pipes

- Successful Pipe Internal Projects require some specialist knowledge - contact our team for assistance

-

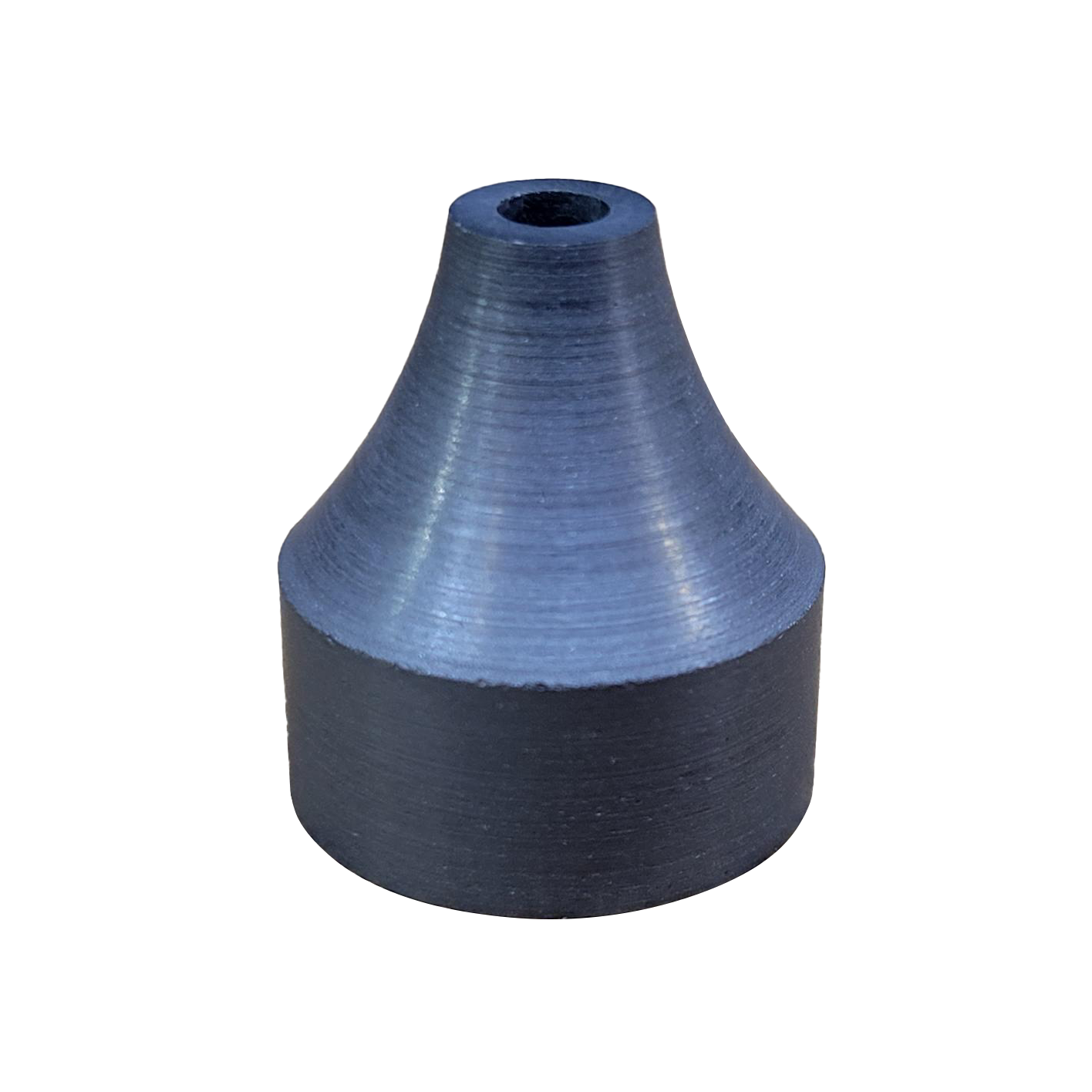

IPC4002H

- Extended Life replacement tip for the ConeBlast Internal Pipe Blasting tool

- Boron Carbide composition

- Recommended for longer-run projects or any project using an aggressive media type

- Lower-cost IPC4002 option available if extended life is not required

IPC4002H- Extended Life replacement tip for the ConeBlast Internal Pipe Blasting tool

- Boron Carbide composition

- Recommended for longer-run projects or any project using an aggressive media type

- Lower-cost IPC4002 option available if extended life is not required

-

BAHNGKit

The “Blast Nozzle Pressure Test Kit” (SKU: BAHNGKit) by BlastOne ensures quick and accurate nozzle pressure testing. Comes complete with a stainless steel pressure gauge, needles, and a protective leather-bound case.

- For testing air pressure at the nozzle

- Test kit includes:

- Liquid filled stainless steel pressure gauge with dual pressure & efficiency scale

- Four needles and instructions

- Protective leather bound case

BAHNGKitThe “Blast Nozzle Pressure Test Kit” (SKU: BAHNGKit) by BlastOne ensures quick and accurate nozzle pressure testing. Comes complete with a stainless steel pressure gauge, needles, and a protective leather-bound case.

- For testing air pressure at the nozzle

- Test kit includes:

- Liquid filled stainless steel pressure gauge with dual pressure & efficiency scale

- Four needles and instructions

- Protective leather bound case

-

INH131PBAGThe “Blast Nozzle Wear Size Analyzer Gauge” (SKU: INH131PBAG) efficiently determines the internal diameter and wear level of a blast nozzle orifice, ensuring optimal blasting performance.

- Used to determine the internal diameter of a blast nozzle orifice

- Allows you to determine the level of wear of the blast nozzle

- Comes with a removable cap and crayon

- Has size markings to allow you to see quickly what size your nozzle is

- Sold Individually

INH131PBAGThe “Blast Nozzle Wear Size Analyzer Gauge” (SKU: INH131PBAG) efficiently determines the internal diameter and wear level of a blast nozzle orifice, ensuring optimal blasting performance.- Used to determine the internal diameter of a blast nozzle orifice

- Allows you to determine the level of wear of the blast nozzle

- Comes with a removable cap and crayon

- Has size markings to allow you to see quickly what size your nozzle is

- Sold Individually

-

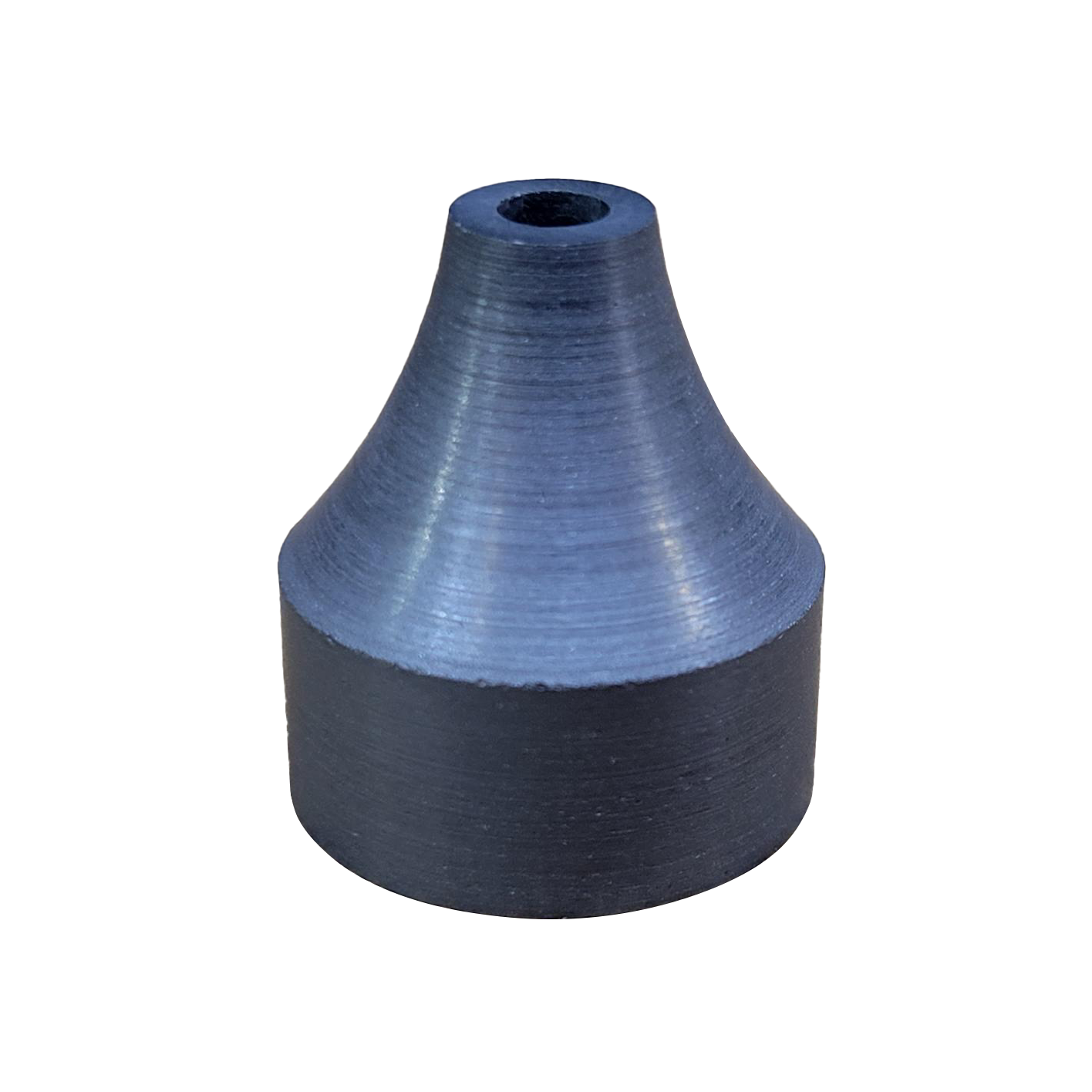

IPC4002

- Replacement tip for the ConeBlast Internal Pipe Blasting Tool

- Tungsten carbide composition

- Recommended for short-run projects or projects using less aggressive media types

- If tips with longer life are needed, use the IPC4002H version

IPC4002- Replacement tip for the ConeBlast Internal Pipe Blasting Tool

- Tungsten carbide composition

- Recommended for short-run projects or projects using less aggressive media types

- If tips with longer life are needed, use the IPC4002H version

-

Thread adapters are a convenient way to allow nozzles of one thread type to be used in nozzle holders of a different type. Boron Carbide is the longest life version, but not available in all configurations. Polyurethane, steel, aluminum, etc. are also available and are lower in cost.

- Available configurations:

- Contractor 50mm Thread Nozzle Holders to:

- 20mm Medium Thread nozzles

- 32mm Fine Thread nozzles

- Flange nozzles

- Fine 32mm Thread Nozzle Holders to:

- 20mm Medium Thread nozzles

- 50mm Contractor thread nozzles. This is a BlastOne Exclusive!

- Contractor 50mm Thread Nozzle Holders to:

- Available configurations:

-

BNATC360CTIP

- Replacement Tungsten Carbide Deflector Tip for BNATC360C internal pipe blasting nozzle.

- Ensures optimal blasting efficiency and durability.

BNATC360CTIP- Replacement Tungsten Carbide Deflector Tip for BNATC360C internal pipe blasting nozzle.

- Ensures optimal blasting efficiency and durability.

A TIP ON WHEN TO REPLACE YOUR SAND BLAST NOZZLE

Even a very small increase in blasting nozzle size will result in a very large increase in ‘air and abrasive consumption’. When worn 1/16” (2mm) larger, it is time to be replaced. Use a size analyzer kit to check your nozzle regularly (we recommend at least ONCE PER WEEK). You’ll be surprised how much your production decreases with a worn sand blasting nozzle! Wet blasting & WIN (Water Induction) also available

SANDBLASTING & ABRASIVE BLAST NOZZLES

NOTE: Efficiency drops 1.5% for every 1 psi below 100 at the sand blasting nozzle. This means a 14% efficiency drop at 90 psi, 26% efficiency lost at 80 psi and almost half lost at 60 psi. Efficiency goes up as pressure increases. 120 psi improves performance by 30%. Actual efficiency increase/ decrease will vary depending on abrasive type and size, blast nozzle type, size and wear, hose sizes and wear, temperature, moisture content of compressed air, etc. Use a abrasive wet or dry blast nozzle pressure gauge to measure air pressure at the nozzle. Make allowance for increased air consumption due to wear, air leaks, breathing airline filter, respirator breathing air and any pneumatic equipment using air from the compressor. A good rule of thumb is to use a compressor twice the capacity of the grit consumption.

My Account

My Account