Heavy Duty Sand & Abrasive Blast Nozzles

ABRASIVE MEDIA SANDBLASTING NOZZLES

BlastOne is a leading supplier of sandblast nozzles to industrial blast and paint companies worldwide. Our team is able to recommend the best type for your application whether you seek long lasting sini silicon nitride nozzles with a tough polyurethane jacket, tungsten carbide lasting 100-250 hours, standard silicon carbide or even alumina.

We also offer our blast nozzles in either contractor, medium, or fine threaded options. Whether you’re interested in trying a new type or simply replace an old favorite, give BlastOne a call and let us ship one out today.

Showing 1–15 of 38 results

-

The BlastOne Infinity Blast Nozzle is the latest proprietary advancement in blasting nozzle technology from the innovators behind the SnakeBite silenced nozzle. Engineered for durability and precision, this general-purpose nozzle delivers extended wear life and a consistent blast pattern across a wide range of industrial applications.

- BlastOne’s newest innovation in blasting nozzle design

- Approximately 6" overall length for versatile use. NOTE: For applications with sufficient space, hyper performance is available in our Infinity XL blast nozzle.

- The proprietary design of the silicon nitride liner minimizes internal turbulence

- Urethane outer jacket provides rugged durability

- Jam-resistant contractor threads ensure easy installation

- Available in orifice sizes: #6, #7, and #8

- Delivers consistent blast pattern and reduced abrasive consumption

- SKU: BNINF

-

The BlastOne Infinity XL Performance Blast Nozzle is possibly the fastest blasting nozzle available, boasting a 35% performance increase over standard blast nozzles. This nozzle, which was designed to be high-speed with extended-wear, was engineered by the developers of the iconic SnakeBite silenced nozzle. Developed with an advanced extended venturi and space-age liner, this proprietary innovation maximizes blasting velocity and efficiency in demanding industrial environments.

- Increases blasting performance by 35% over standard blast nozzles

- Latest proprietary design from BlastOne’s nozzle technology line

- 11–13" overall length depending on orifice size. NOTE - for applications not needing the Hyper nozzle performance of the Infinity XL, our 6" long standard Infinity nozzle is excellent and is ideal where access is limited.

- Proprietary silicon nitride liner for low turbulence and long life

- Durable urethane jacket withstands harsh job conditions

- Contractor-grade threads resist jamming during use

- Available in orifice sizes: #6, #7, and #8

- SKU: BNINFXL

-

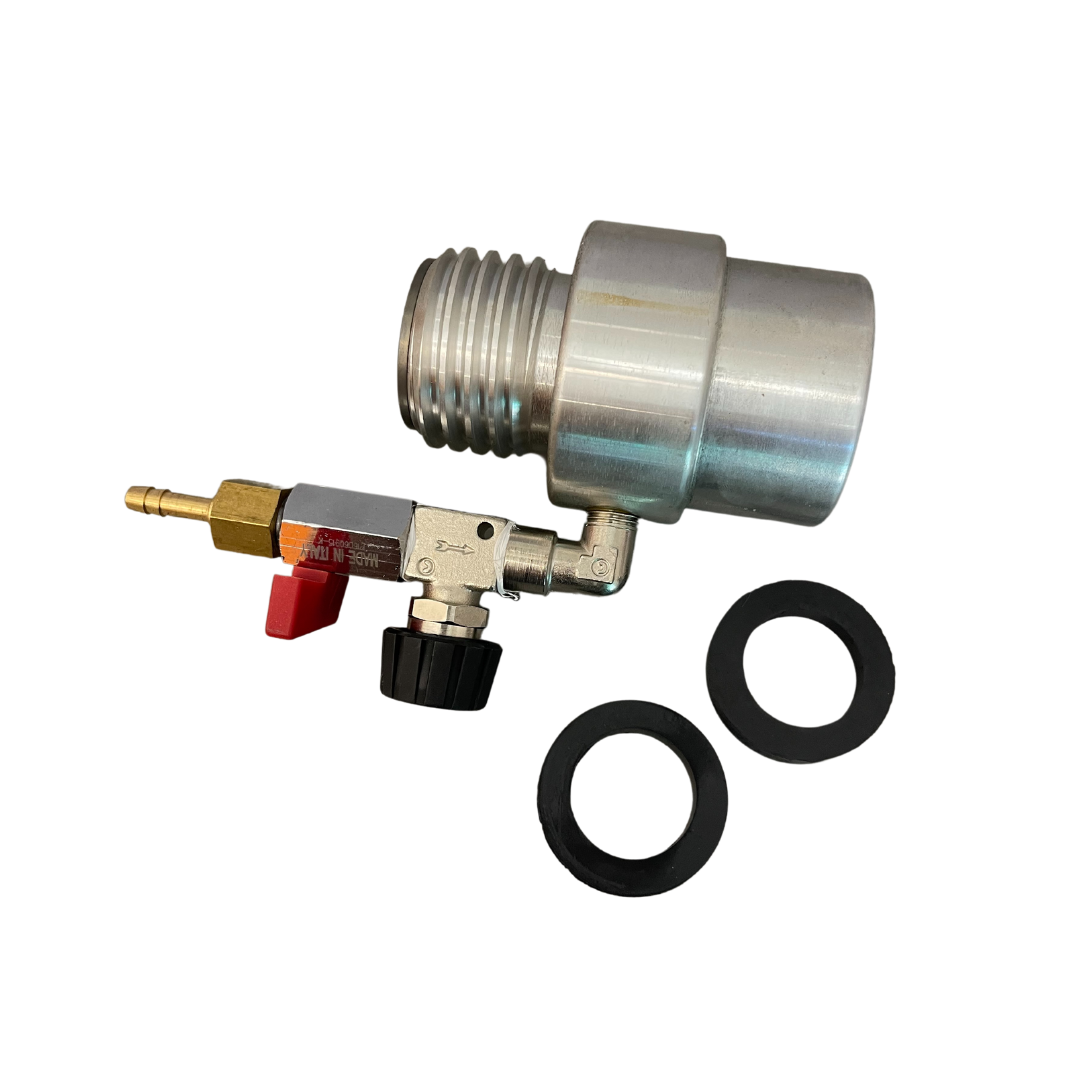

WATER INDUCTION BLAST NOZZLE

- Wet Blast Nozzle

- WIN Nozzle for wet abrasive blasting

- 2" UNC (50mm) coarse Contractor thread

- 1¼" (32 mm) wide throat entry, double venturi

-

Workhead Nozzles include:

- #3 Nozzle for MiniBRS Pistol Grip Workhead (pneumatic and electric)

- #4 Nozzle for MiniBRS Pistol Grip Workhead (pneumatic and electric)

- #4 Nozzle for Right Angle Workhead

- #4 Long Venturi Nozzle for BNV-3

- #6 Long Venturi Nozzle for BNV-3

-

FAN BLAST™ Fan Pattern SiALON Blast Nozzles give wide, even blast patterns, ideal for sweep blasting. Different variations include:

- 2" UNC (50mm) coarse contractor thread

- 1-1/4" ( N.P.S.M.) fine industrial thread

-

BNATC360BOLT

- Replacement bolt for the Internal Pipe 360° Blast Nozzle

- Sold - individually

BNATC360BOLT- Replacement bolt for the Internal Pipe 360° Blast Nozzle

- Sold - individually

-

BlastOne's SnakeBite XP Blast Nozzle is the high-performance alternative to the popular SnakeBite XQ silenced configuration. Designed for professionals seeking maximum blasting efficiency, the XP model utilizes a simple bump cap instead of a silencer, resulting in unmatched speed and performance without the noise and thrust reduction features of its counterpart.

- Performance:

- The advanced modeling used when designing this Snakebite XP hyper nozzle has taken blasting performance to a whole new level. The refined internal geometry coupled with the non-silencing bump-cap produces very fast cleaning speed indeed.

- Liner:

- The new internal geometry when combined with the silicon nitride composition extends usable life greatly.

- Jacket:

- Anodized aluminum with ergonomic shape makes for a very comfortable grip.

- Sizes:

- Available in the following orifice sizes: 6, 7, 8, & 10

- Overall length varies from 10" to 13", depending on orifice size.

- Thread type:

- Available in standard 2" Contractor thread only. (See You May Also Like nozzle thread adapters below if you want to use with fine thread nozzle holders.)

Note: Inquire for details about our free trial offer.

- Performance:

-

- 2" UNC (50mm) coarse Contractor thread 'C' or 1 1/4" NPSM (32mm) Fine Industrial thread 'F'

- Square thorat entry, venturi

- Tungsten carbide liner

- Urethane jacket, brass thread

- Large square blast pattern - less overlap when blasting

- Alignment ridges on jacket

-

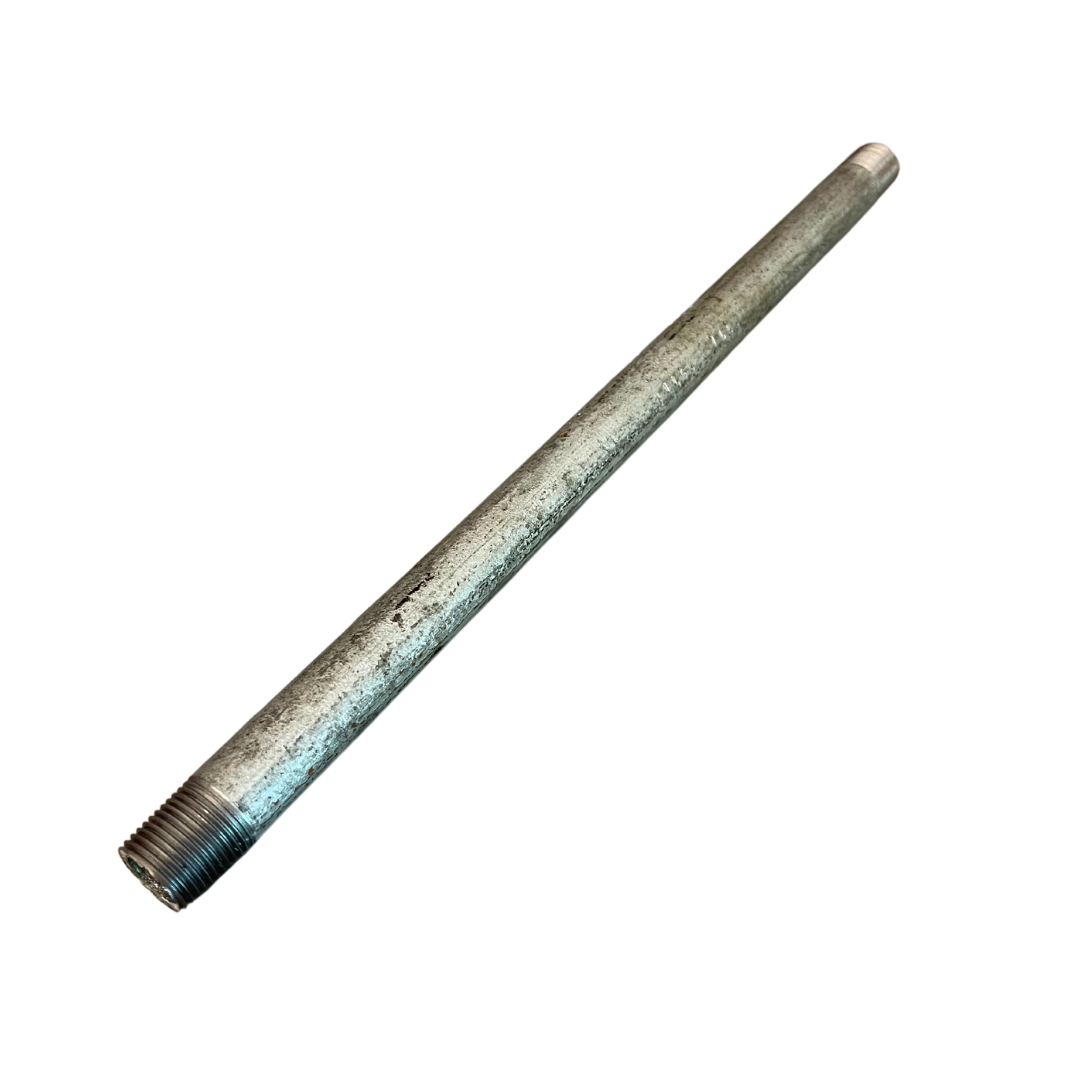

Refresh your Tite Space Invader Blasting Kit with replacement repair rods. Comes in various lengths from 30 - 152 centimetres.

- Durable and long-lasting construction

- Easy-to-use design for quick repairs

- Compatible with a variety of pipe sizes and materials

-

Tite-Space nozzles are angle nozzles, designed for use in areas that are especially difficult to access, and feature:

- 3/8" NPT Thread in either Male or Female configuration

- Male version has brass threads and requires a minimum opening clearance of 1". This version is 1-7/8" long.

- Female version has steel threads and requires a minimum opening clearance of only ¾". This version is 3-1/8" long.

- These nozzles are often used in conjunction with our Tite Space Invader Blasting Kit, available here

- Angle options include:

- 45° & 60° forward blast

- 90° right angle blast

- 135° reverse blast

- Some options available in double, triple or quad orifices in addition to single.

- Note: Using nozzles with multiple orifices will multiply the compressed air CFM requirement accordingly.

- Stock version uses tungsten carbide lining.

-

The blast nozzle for the ConeBlast Internal Pipe Blaster is a key element in controlling the volume of air/abrasive flow. It is subject to high wear and is a common replacement part. Additional details:

- Sizes. Two sizes are available, depending on the capacity of your compressed air source.

- BNAFR8 requires 250CFM

- BNARF10 requires 400CFM

- (The size variants are interchangeable.)

- Construction. These nozzles are made from tungsten carbide. For large pipe-cleaning projects, contact us for options on longer-life versions.

- Sizes. Two sizes are available, depending on the capacity of your compressed air source.

A TIP ON WHEN TO REPLACE YOUR SAND BLAST NOZZLE

Even a very small increase in blasting nozzle size will result in a very large increase in ‘air and abrasive consumption’. When worn 1/16” (2mm) larger, it is time to be replaced. Use a size analyzer kit to check your nozzle regularly (we recommend at least ONCE PER WEEK). You’ll be surprised how much your production decreases with a worn sand blasting nozzle! Wet blasting & WIN (Water Induction) also available

SANDBLASTING & ABRASIVE BLAST NOZZLES

NOTE: Efficiency drops 1.5% for every 1 psi below 100 at the sand blasting nozzle. This means a 14% efficiency drop at 90 psi, 26% efficiency lost at 80 psi and almost half lost at 60 psi. Efficiency goes up as pressure increases. 120 psi improves performance by 30%. Actual efficiency increase/ decrease will vary depending on abrasive type and size, blast nozzle type, size and wear, hose sizes and wear, temperature, moisture content of compressed air, etc. Use a abrasive wet or dry blast nozzle pressure gauge to measure air pressure at the nozzle. Make allowance for increased air consumption due to wear, air leaks, breathing airline filter, respirator breathing air and any pneumatic equipment using air from the compressor. A good rule of thumb is to use a compressor twice the capacity of the grit consumption.

My Account

My Account