Blast and Vacuum Blasters

Showing all 8 results

-

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Blasting rate up to 2 m2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Blasting rate up to 2 m2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

-

- Electric vacuum available - wet & dry (HEPA)

- Best used with

-

- TFP200 Deck Scaler

- SF11 Deck Hammer

- Peening Prep Tool

- Trelawny range of Hand Scalers

- Pneumatic vacuum available – wet & dry (HEPA)

- Best used with

-

- Trelawny range of EX tools for use in explosive environments

- VL303 Needle Scaler

- SF1 Scaling Hammer

- SF11 Deck Hammer

- Trelawny range of EX tools for use in explosive environments

-

Many time-saving Vac Hose Fittings are available. This group includes:

- Barbed & smooth Vac Hose Menders

- Reducing Joiners, to transition larger hose to smaller one

- Suitable for repairing or joining hoses

- Connect same size hoses or adapt different sizes together

- Easy to install and remove for hassle-free maintenance

- Available in multiple types, including carbon steel and zinc-plated steel.

-

VCVRS3

- This Blast and Vacuum system is built for high production vacuum blasting work.

- The Vacuum system, blast machine and airdryer are all mounted to one skid.

- The abrasive does not recycle which is ideal when you have very low dust requirements or when your specification calls for the use of virgin abrasive only.

- This system is 100% pnuematic and does not require any electrical power.

- Blast Pot capacity is 3.5 cuft.

- Blast upto 60 sqft / 6 sqm per hour

- Requires 750cfm of air

VCVRS3- This Blast and Vacuum system is built for high production vacuum blasting work.

- The Vacuum system, blast machine and airdryer are all mounted to one skid.

- The abrasive does not recycle which is ideal when you have very low dust requirements or when your specification calls for the use of virgin abrasive only.

- This system is 100% pnuematic and does not require any electrical power.

- Blast Pot capacity is 3.5 cuft.

- Blast upto 60 sqft / 6 sqm per hour

- Requires 750cfm of air

-

- Complete Range of blast and vacuum work heads and equipment

- Typically work best on flat surfaces, custom units are available upon request

- Largest workhead available - Large with Wheels

- Pistol Grip - *Most Popular* easiest to hold onto

- Right Angle - Designed to get into smaller areas

- Standard Unit - the Original Blast and Vac head

- aka: Blastnvac 6 Head

- Choose your style

-

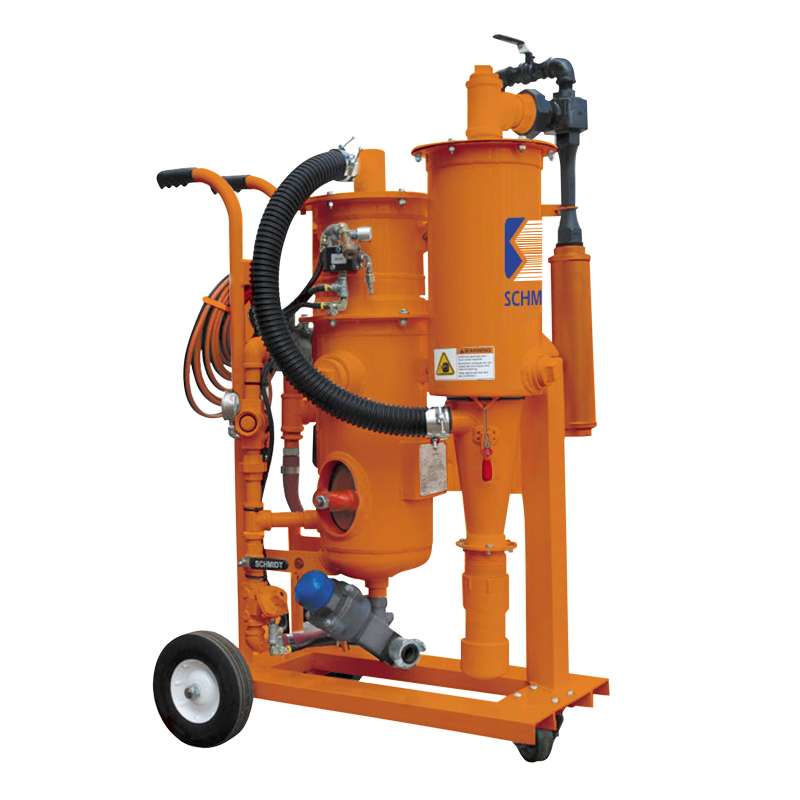

VCBRS35

- Abrasive holding capacity of 3.5 cu ft / 100 litres

- Blasting rate up to 4.0 m2 per hour

- Compressed Air Requirement 750 cfm

- On wheels for easy access. Includes fork pockets

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

VCBRS35- Abrasive holding capacity of 3.5 cu ft / 100 litres

- Blasting rate up to 4.0 m2 per hour

- Compressed Air Requirement 750 cfm

- On wheels for easy access. Includes fork pockets

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

-

VCBRSMPBRS - Abrasive Blast & Recovery System

- Abrasive holding capacity of 0.3 cu ft / 8.5 liters

- Blasting rate up to 2.0 m2 per hour

- Compressed Air Requirement 185 cfm

- On wheels for easy access. Includes fork pockets

- Recirculating compact blast & recovery unit

- 100% compressed air driven - no electricity required

VCBRSMPBRS - Abrasive Blast & Recovery System- Abrasive holding capacity of 0.3 cu ft / 8.5 liters

- Blasting rate up to 2.0 m2 per hour

- Compressed Air Requirement 185 cfm

- On wheels for easy access. Includes fork pockets

- Recirculating compact blast & recovery unit

- 100% compressed air driven - no electricity required

-

VCVRS2

- For blast and vacuum work with no abrasive recycling, when only virgin abrasive is to be used

- Blast up to 3.0 m2 per hour

- 1.0 cu ft / 28 litres abrasive capacity of blast vessel

- Minimum air supply of 200cfm/100psi is required to run this unit

- Excellent portability, plus the productivity benefits of pressure blasting

- 100% compressed air driven - no electricity required

VCVRS2- For blast and vacuum work with no abrasive recycling, when only virgin abrasive is to be used

- Blast up to 3.0 m2 per hour

- 1.0 cu ft / 28 litres abrasive capacity of blast vessel

- Minimum air supply of 200cfm/100psi is required to run this unit

- Excellent portability, plus the productivity benefits of pressure blasting

- 100% compressed air driven - no electricity required

My Account

My Account