Abrasives

Showing 1–15 of 17 results

-

- Armex Blasting Media is a premium baking soda/Sodium Bicarbonate

- Originally designed in 1984 to restore the Statute of Liberty

- Manufactured by Church and Dwight

- Predominately used to remove stuff off delicate substrates

- Sold by the pallet (pallet minimum)

- Abrasive cannot be ordered online at this time

-

GMA ToughBlast Garnet Abrasive is an engineered blend designed to power through the most demanding coating removal projects. Ideal for industrial sandblasting, this high-performance abrasive combines the cutting power of hard rock garnet with the durability of alluvial garnet, delivering faster results, cleaner finishes, and reduced consumption.

- Removes thick coatings (15–30 mils) with superior speed and efficiency

- Delivers a uniform surface profile of 70–90 μm (3.0–3.75 mil)

- Blasting rates up to 30 m²/hr and low dust levels for safer operation

- Engineered for shipyards, tank farms, petrochemical, and infrastructure maintenance

- Cost-effective with lower abrasive consumption (as low as 16kg/m²)

- Recyclability rated at 4/10 with low-to-medium dust factor

- Available in 16 and 36 mesh sizes

- MilSpec approved for consistent quality and performance

- SKU: P-GXTB | MPN: GX2

-

Also known as Brown Fused Alumina, Brown Fused Aluminium Oxide Abrasive Media Is a Long Lasting and Sharp abrasive used for high-performance applications and general industry use. Aluminium oxide is very hard and aggressive and is commonly used for mixing with paint coatings for nonslip surfaces. White aluminum oxide also available.

-

- Manufactured cast haematite iron abrasive

- Grey, angular granules

- High performance, hard, sharp abrasive

- Used in airblast rooms

- Maintains sharp angular shape as it wears

- Can be recycled many times

- Packed in 25kg bags

-

Stainless Steel Shot

- Manufactured chronital stainless steel shot abrasive

- Can be recycled many times, up to 100

- Stainless Steel Abrasives are also used in applications where there can be no ferrous contamination

- Used mainly in an air-blast application to create a specific desired finish or where a non-ferrous abrasive is required

- Sharp edges gradually round over as it wears

- Packed in 25kg bags

- Made by Vulkan Shot

- Grittal Stainless Steel Grit also available

-

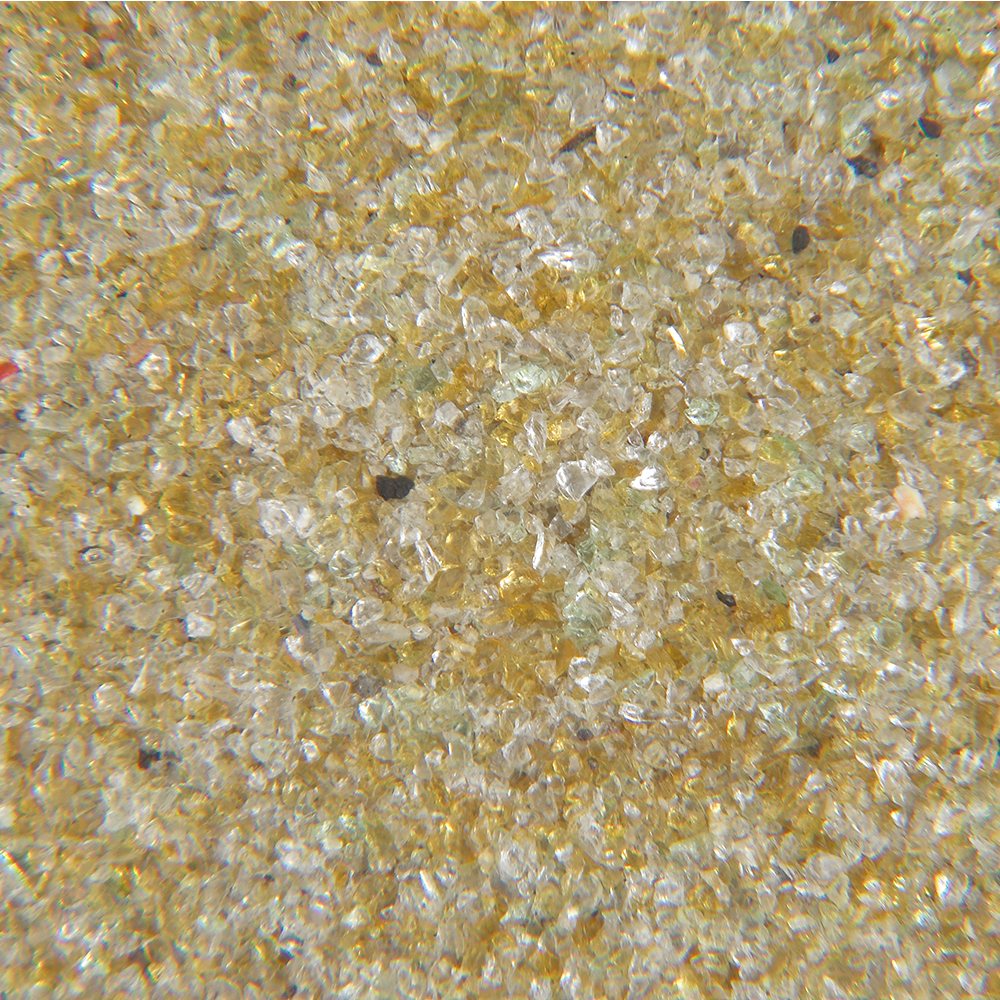

Crushed Glass Abrasive Sandblasting Media (SKU: P-CG) is a versatile, angular-shaped abrasive designed for steel profiling and concrete blasting. Made from recycled glass, this eco-friendly media is available in various grades and packaging sizes, perfect for tackling heavy coatings, rust, and mill scale.

Features:

- General-purpose abrasive: Ideal for moderate steel profiling and concrete blasting.

- Angular shape: Creates a sharp profile for removing heavy coatings.

- Eco-friendly: Made from cleaned, crushed, and recycled glass.

- Grades available: 12/20, 12/40, 20/40, 30/60, 40/70, Extra-Coarse, Coarse, Medium, Fine, Extra-Fine.

- Packaging options: 4000lb & 2000lb bulk bags, 100lb, 80lb, and 50lb bags.

- Blasting speed: 50–150 ft²/hr; Consumption rate: 5–12 lb/ft².

- Note: Not recommended for blasting on stainless or aluminum

-

- Manufactured glass abrasive

- Miniature, translucent glass spheres

- Potters glass beads, Ballotini Impact Spheres

- Milspec glass beads available as an option

- Spherical beads impart a satin or matte 'shot peened' finish to the work surface

- Widely used in hand cabinets for surface cleaning rather than surface etching

- Can be recycled

-

GMA SpeedBlast Garnet Abrasive Media for Sandblasting is an economical, high-performance abrasive ideal for general-purpose surface preparation. Made from natural Australian garnet, it offers fast cleaning rates, low dust emissions, and a uniform profile for optimal coating adhesion.

- General-purpose abrasive for industrial surface preparation

- Produces a consistent surface profile of 50–100 microns (2.0–4.0 mil)

- Blasting rates: 15–20 m²/hr with consumption of approx. 320 kg/hr

- Low dust, sub-rounded grain for cleaner visibility and safer operation

- Compatible with wet and dry blasting systems

- Economical and recyclable, made from inert natural garnet mineral

- Suitable for commercial buildings, plants, processing facilities, and more

- SKU: P-GASB | MPN: GASB

-

The GMA Classic Cut 80 Mesh Garnet Abrasive Media is a high-performance abrasive ideal for sandblasting and water jet applications. Perfect for new steel preparation and mill scale removal, this #80 mesh garnet delivers a 1–2 mil profile, low dust generation, and high productivity, exceeding 20 m2/hr on mill scale. It’s economical, recyclable, and meets ISO quality standards. Features:

- Applications: New steel, mill scale, rust, and coating removal.

- Blasting rate: Over 20 m2/hr for mill scale; consumption ~250 kg/hr.

- Low dust generation: Cleaner, more efficient operation.

- Recyclable: Single-use or multiple recycling cycles.

- Meets ISO 11126/11127: Tested for quality and safety.

- Packaging: Available in skid quantities or bulk orders.

-

GMA PremiumBlast 30/60 Garnet Abrasive Media for Sandblasting offers a balanced blend for high-efficiency coating removal and rust treatment. Engineered for consistent performance and reduced dust, this economical abrasive media supports general industrial maintenance and precise surface preparation.

- Ideal for coating removal and medium-to-heavy rust treatment

- Produces a consistent surface profile of 60–100 microns (2.5–4.0 mil)

- Blasting rates: 15–20 m²/hr with a consumption rate of approx. 320 kg/hr

- Sub-rounded, pink to reddish-brown garnet grains minimize dust and enhance visibility

- Safe, inert natural mineral with very low silica content

- Compatible with wet and dry blasting systems

- Economical for single use and recyclable in suitable applications

- SKU: P-GAPB | MPN: GAPB

-

ASUREA304025

Type II, a thermoset Urea Formaldehyde, meets the specifications of MIL-P-85891A.

The finished product contains no inorganic fillers & is treated with an anti-static agent. Type II Urea is commonly used as an abrasive, blast media & filler.

Plastic media - Type II (urea), size 30/40 mesh MIL-P-85891 approved

Other sizes available STANDARD MESH SIZES 8/12, 12/16, 12/20, 16/20, 20/30, 20/40, 30/40, 40/60, 60/80 Non Milspec Material also availableASUREA304025Type II, a thermoset Urea Formaldehyde, meets the specifications of MIL-P-85891A.

The finished product contains no inorganic fillers & is treated with an anti-static agent. Type II Urea is commonly used as an abrasive, blast media & filler.

Plastic media - Type II (urea), size 30/40 mesh MIL-P-85891 approved

Other sizes available STANDARD MESH SIZES 8/12, 12/16, 12/20, 16/20, 20/30, 20/40, 30/40, 40/60, 60/80 Non Milspec Material also available -

Black Silicon Carbide Abrasive media is a manufactured ceramic abrasive - extremely hard, aggressive, high performance abrasive used for cleaning and preparing very hard surfaces. Another name for Silicon Carbide is Carborundum. Silicon Carbide Abrasive has Mohs hardness of 9.0 - which very close to diamond (the hardest substance known to man) this is what makes Silicon Carbide a cost effective abrasive when contained and recycled? Carborundum or Silicon Carbide Abrasive Grain, can be mixed with paint coatings for creating high wear nonslip surfaces & non-slip flooring.

-

- Manufactured cast steel grit abrasive

- Used mainly in airless wheel blast machines & blast rooms

- Blue grey, angular granules (GL = blue, GH = grey)

- Can be recycled many times

- High performance, cleaning and descaling abrasive

- Sharp edges gradually round over as it wears

- Standard GL and GH hardness grit

- Special GP hardness and other specifications available

- Manufactured to conform to: SAE J444, SAE J1993, SFSA 20-66

- Hardness: GL = 56-60 HRc, GH = 60-65 HRc

- Packed in 25kg bags

-

Steel Shot Abrasive in Australia

- Steel shot - manufactured hypereutectoid, metal spheres used in airless centrifugal wheel blast machines to clean foundry castings, surface polishing and shot peening

- Also used in portable trackblast airless wheel blast machines for concrete floor preparation, blasting ship decks and profiling

- Quality Steel Shot is very long lasting

- Steel Shot can be recycled many times

- Hardness: 40-50 HRc. Other hardness's of steel shot are available on request

- Special, Stainless Steel Shot and High Hardness, Milspec (Military Specification Peening Steel Shot) specification shots available

- Manufactured to conform to: SAE J444, SAE J827, SFSA 20-66

- Steel Shot is packed in 25kg bags, drums or bulk bags

- BlastOne is a leading steel shot supplier in Australia & New Zealand

-

Also known as White Fused Alumina, White Fused Aluminium Oxide Abrasive Media Is a Clean and Sharp abrasive used for high-performance and delicate blasting and cleaning projects, including cleaning of hi-tech metals. White Fused Alumina is an inert material with excellent abrasive qualities & available from most BlastOne branches in Australia. Brown aluminum oxide also available.

My Account

My Account