Why use Multi-Operator Blasting Systems?

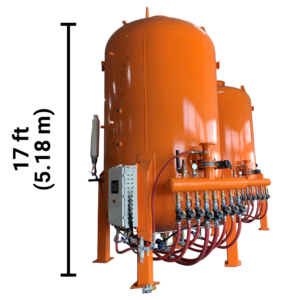

Many years ago, large blasting projects were completed using multiple blast machines, each operator having his own blast machine. Subsequently, bulk blasting machines were developed to increase the efficiency of multi-operator blasting projects. The biggest time/cost saver of using a bulk blaster is reducing the time spent refilling the blast machine. Typically, they are filled at the start of a shift and do not need refilling till the end of it. Not only do they reduce the refill labour in filling the pot but the lost time for the blast operator waiting for the pot to be refilled is minimized as well.

In addition, bulk blasters keep the abrasive dryer. This because every time a blast machine depressurizes, a fresh load of wet air enters. By only pressurizing once per shift the constant reintroduction of moist air is reduced. Dryer air equals better flowing abrasive.

Common issues with Multi-Operator Blasting Systems

BlastOne bulk blasters are designed for easy high productivity use and are largely problem free to operate if operated by skilled personnel.

Consideration does need to be given to how they will be loaded. Manual loading from small bags or my shovel is not possible and has to carried out by crane, forklift, or blower truck. This means that the bulk blaster needs to be accessible to this type of equipment.

One issue that does also occur is the fact that not all abrasive is fed out of the bulk blaster. All granular materials have an angle of repose (angle that they will free flow by gravity). Being heavy materials, abrasive blasting materials have a fairly steep angle of repose. The design requirements for a bulk blaster preclude having a base that will give an angle of repose that assist enter evacuation of abrasive. Therefore, there will always be a small amount of abrasive remaining in the bottom of the bulk blaster which may require either removal by vacuum or shovel

Important considerations when choosing the right Multi-Operator Blasting Systems

One of the key decisions when choosing a bulk blaster is whether the worksite where it will eb used will allow refilling by crane or blower truck. As stated above manual filling is not viable

Available compressor size also is a consideration. 4 operators blasting with No.7 nozzles will require a minimum of 1200 cfm. A compressor upsize may be required as well as the purchase of the bulk blaster.

Another choice to be made is whether a highway or yard towable trailer is required. A highway towable trailer has much more stringent design and certification requirements to enable it to be used on public roads and with this comes attendant increased costs. If highway towable is not an absolute necessity, then yard towable may be more economical.

My Account

My Account