Industrial Marine Blast & Paint Facilities

BlastOne has a long history of working with marine operators and maintenance providers to keep the world’s shipping afloat. Each job has unique challenges and we work with you to find the fastest, safest and cleanest solution for your team.

The correct application of protective coatings relies on the correct coating equipment being used. BlastOne has extensive experience in all aspects of marine protective coatings. From brushes and rollers to high-tech plural component spraying systems, BlastOne is your one-stop-shop source of supply.

Nowhere else do you see rust on such a large scale as you do in a shipyard. Here are a few common issues we’ve found from working with the industry:

Ships work in a very corrosive environment. Seawater contains salt, which speeds up the corrosion process. Considering the ship is almost always wet and at times, travels through warm, tropical areas, corrosion occurs quickly.

Marine assets require an impenetrable barrier to protect them from corrosion. These assets are very expensive to build and, when in service are significant profit centers for their owners. When the ships are out of service, large losses in productivity and opportunity costs ultimately lead to a loss of profits.

Abrasive blasting is the best way to ensure the surface is ready to partner with the coating to provide long-term corrosion protection.

The Best Blasting Equipment

Big projects require a think big attitude. And when it comes to corrosion control, they don’t come much larger than marine industry projects.

Upsize No.1 – The Blast Pot – Your standard sized one or two man blast pot will no longer be sufficient. Ships earn their keep when afloat, not sitting on a dry dock. Blasting operators are always under pressure to get their job done to get commercial vessels operating again. How do we increase productivity when blasting with multiple operators? While it is possible to put multiple one/two man pots around a blast site, a better solution is a bulk blaster. These start at 75 cu.ft. capacity (as opposed to a one /two man pot with 6 to 10 cu.ft.) and go up to 160 cu.ft. capacity. The big efficiency gained here is only filling the blaster once a day. These units can run multiple operators for an entire shift without requiring refilling – no time lost on blowdown, filling and restarting.

Upsize No.2 – The Blast Hose – Having improved blast site efficiency by converting to the use of bulk blasters. The next item to upsize is the blast hose. Because of the ability to blast continuously, a large flat surface such as a ship’s hull will justify upsizing your blast set-up. More complex structures that require stop/start blasting for access reasons may not get the full efficiency advantage of set-up upsizing. So, when blasting a ship hull, increase your blast hose to a minimum of 1½” ID, 2” is even better. If not for the whip end, at least use larger blast hose for the extension lengths.

Upsize No.3 – The Blast Nozzle – Having upsized your blast hose, it’s now time to upsize your nozzle. With enough abrasive coming through and with reduced restrictions in the hose, and now being able to move freely, the operator can now get the advantages of using a bigger nozzle – wider pattern and higher abrasive flow.

Upsize No.4 – Spent Abrasive Recovery – Ship blasting goes from great access outside to very poor access inside. Cramped compartments and ladder only access combine to make manual recovery of spent abrasive, tedious, heavy, and slow. The answer? The abrasive was blown in there pneumatically, suck it out pneumatically as well. Vacuum recovery systems remove the manual labor of “a man and a wheelbarrow”. Place the pick-up tool in a pile of spent abrasive, and it’s gone.

Upsize No.5 – The Compressor – Having upsized everything else in your blast system, it’d now time to look at your compressor. Multiple operators means multiple nozzles and helmets and a vacuum recovery system can consume as much or more compressed air as a large blast nozzle. To calculate compressed air requirements, add up the total air consumption required for breathing air, nozzles, and vacuum and then another 30 to 50% to allow for losses and compressor wear.

DIFFERENT ABRASIVES USED IN SHIPYARDS

The most common types of abrasives used during maintenance work or in a dry dock are expendable abrasives. The range of expendable abrasive blasting media includes:

Industry preference leans towards abrasives that remove more, remove it faster and remove it leaner. Two “rules of thumb” guide selecting abrasive size: “the grain size of the abrasive should match or be slightly larger than thickness of the contaminant being removed” and “highest productivity is achieved when there is a blend of grain sizes in the working mix”. Since the contaminants requiring removal are thicker in the marine industry, the size range of your abrasive needs to include a higher proportion of larger sized grains and higher pressure will also improve productivity. An additional necessary consideration is balancing abrasive consumption costs and waste disposal costs. A particular abrasive may be more expensive to buy, but if it does more work with less material, there is less waste to dispose of, and consequently helps to reduce the overall job cost.

Many contractors have turned to GMA ToughBlast and GMA NewSteel because of their outstanding in their performance in blasting more area in the same time and with less material.

Coating Types and Equipment

A broad range of coatings are used by the marine industry. The world’s marine fleet operates in extremely harsh environments. The coatings that can stand up to these environments must be able to withstand the forces that would attack them – heat, chemical and mechanical. Many of these coatings are described as ultra-high build. For ship hull exteriors, anti-fouling prevents the growth of marine life on them. Ship decks have elastomeric coatings applied to them. Usually with an aggregate dropped into it to add non-skid characteristics. On the inside of tanks, there are solventless epoxies and surface tolerant epoxies that will cope with minimal amounts of flash rusting. Many of these coating have a dry film coating thickness of around about 20-40 mils. Offshore oil rigs have Passive Fire Protection (PFP) coatings.

Airless sprayers are most commonly used when spraying ultra high build coatings. Plural component sprayers automatically blend multiple components that have a short pot-life, to reduce human error or to cut down on waste. One of the most common sprayers found in shipyards is the Graco 60:1 NXT. Becoming more popular are the Graco 45:1 and 70:1 XL pumps which provide extra volume and allow running multiple guns over longer distances.

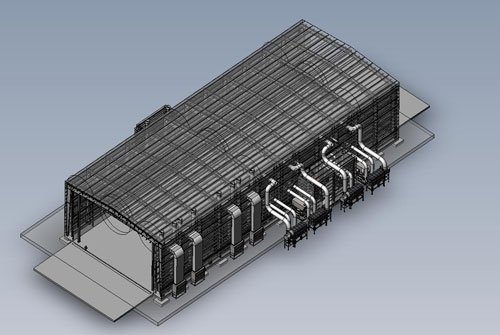

Blast and Paint Halls for Ship Modules

BlastOne has a long track record of supplying blast and paint halls for ship modules.

Large enclosed halls are designed and engineered to provide ventilation and visibility for both painting and grit blasting. The abrasive recycling systems and high performance vacuums provide work efficiency, while humidity controlled air helps prevent oxidation and flash rusting of the steel between the blasting and coating processes.

The configuration of the rooms can be designed around the ship modules to be coated. Ventilation systems are designed for end draft or downdraft configurations.

Normally, because of the size of the rooms, a separate structure is required for the booth roof and building trusses.

My Account

My Account