SNAKEBITE XQ SAVES THE DAYLIGHT FOR AIRPORT BLASTING CONTRACTOR – LITHKO RESTORATIONS

Lithko Restorations were successful in winning a large blasting project at the Columbus Airport. The project was to sandblast (remove) the parking lines from the floor of the garage that was being converted from a rental car facility into a parking garage as part of the Airport Upgrade.

The unique challenge was – due to the proximity of the project intermingling with airport travelers, Lithko was contract-mandated to maintain noise under 90 dB at an entrance of the passenger terminal, and have no visible airborne dust beyond 50ft from where they would be working.

PROJECT OVERVIEW

Lithko started the project renting a high performance mist blaster skid from BlastOne, combined with BlastOne’s Garnet which ensured there was no airborne dust. The noise of blasting however was measured at 104 dB and received airport noise complaints. Lithko was forced to stop blasting during the day and could only blast at night, which significantly impacted the length of the project due to working hours, conditions, and available labor.

BlastOne Introduced the SnakeBite XQ blast nozzle to this project, which effectively dropped the blasting decibels from 104 dba down to 86 at the nozzle, allowing the Lithko team to start blasting again during the day.

RESULTS

The XQ nozzle made a profitable impact on the project as the blasting crew were now able to blast longer, in better conditions for the remainder of the project. The project was completed ahead of schedule with no dust or noise complaints.

At the end of the day – the SnakeBite literally saved the daylight for the Blasters at Lithko.

“Thought it was great, a lot quieter than the others (nozzles), and had a wider pattern on it. As far as noise goes, we were allowed to blast during the day time again” – Nathan Palmer, Project Lead

“With the silencer I didn’t have to use any force, it was great.” – Anthony Smith, Technician

Experience the BENEFITS

NOISE REDUCTION

The SnakeBite Flex reduces noise generated by up to 16 dBA – that’s equivalent to up to 75% quieter than standard nozzles, and the typical high pitched screech is now gone.

Reduce the risk of operator and bystander hearing related injuries and increase your ability to comply with workplace noise regulations.

PROJECT TIMELINES

With its reduced noise capabilities, SnakeBite Flex allows other crews to work in the vicinity of blasting, minimizing production disruptions.

EASE OF USE

The unique design of nozzle and silencer reduces operator fatigue by up to 45%. Operators can better maneuver the nozzle and will be less fatigued over the shift.

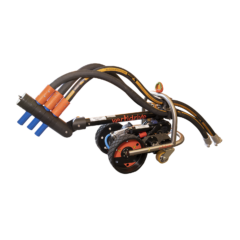

The SnakeBite XQ (Extra Quiet) Blast Nozzle

Comparison with Standard Nozzles

Head-to-Head Against the “Quiet” Competitor

Frequently Asked Questions

Does the reduced thrust compromise productivity compared to standard nozzles?

Productivity of the Flex is comparable with standard nozzles (same size, pressure, media) and the XQ is up to 25% more productive than standard nozzles of the same size. The reduced nozzle kick-back thrust – up to 45% – can actually increase productivity by reducing operator fatigue and enabling a high rate of productivity to continue throughout the shift…. and the #10 Strike (due to the larger orifice size) can increase hand-held blasting productivity up to 54%.

Is 1.25`` hose with a 750cfm compressor sufficient when using the SnakeBite Strike?

It depends on hose length. It is not recommended to use the Strike with a 1.25″ hose longer than 25 feet.Do I need any special equipment to get the SnakeBite noise and thrust reduction?

No, just screw the SnakeBite with the Silencer fitted into a contractor thread nozzle holder, set the pressure to 100psi and start blasting. Blasting noise will automatically be reduced by up to 16 dB and and you will immediately feel around 45% less nozzle thrust – there is nothing else you have to do.What if my nozzle isn't achieving a reduction of 16 dB?

Factors contributing to the optimal reduction in sound pollution include.- Nozzle pressure needs to be between 80-115 psi

- Blasting with lean abrasive flow increases noise

Adjusting these factors will have an effect on dB reduction.

How long will the nozzle last?

Expected wear-life for the SnakeBite is over 400 hours. This is double a standard tungsten carbide nozzle.

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account