COMPANY BACKGROUND

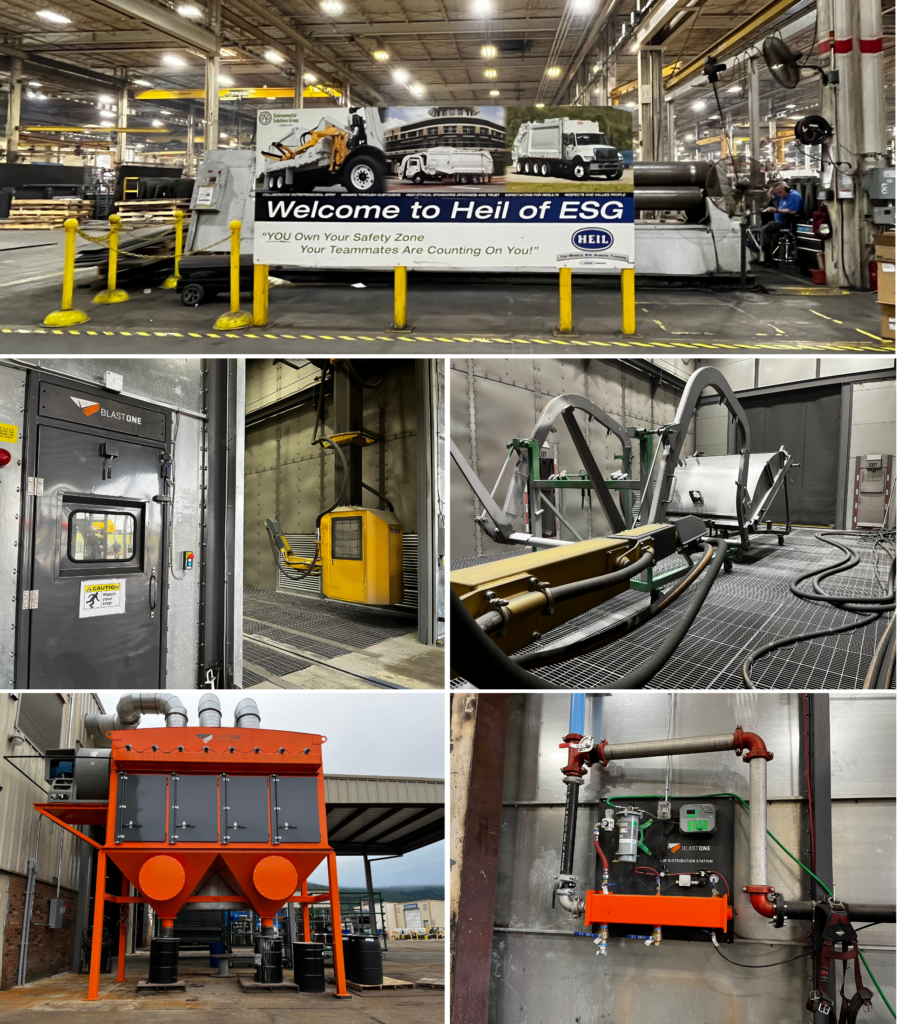

Heil is the industry leader in garbage truck body design and specialized refuse body manufacturing. Since 1901, we have built a reputation for quality, durability, and innovation in the solid waste industry.

PROJECT OBJECTIVES

Improve the quality of finished products

Reduce and eliminate weld splatter on the job site

Increase safety for employees

RESULTS

During the first few weeks of production, the blast booth has reduced labor for surface preparation by 88%. What used to take five men for an hour and a half, now takes 50 minutes for one man. Unanticipated product quality improvement opportunities are already being recognized as the blasting process reveals issues with weld quality that were previously more difficult to identify. Additionally, workers familiar with the grinding process are excited about the substantial upgrade in terms of safety and ergonomics.

SOLUTION

Implemented a robotic blast booth that integrates with the customer’s floor-mounted chain conveyor system to seamlessly transfer workpieces through to paint after blasting. The system leverages a full-underfloor abrasive recovery system to automatically separate blasting waste from reusable abrasive without operator intervention.

HEIL ENVIRONMENTAL INDUSTRIES

THE DIFFERENCE BETWEEN GRINDING VS BLASTING

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account