Industrial Paint kitchens are fire-rated buildings used for the safe storage of hazardous materials and waste. Applications include paint mixing, pumping stations, paint storage and other hazardous material storage. Designed for indoor and outdoor applications, paint kitchens feature explosion relief wall panels and an extra-large spill containment.

Design and Construction of Paint Kitchens

Important Aspects to consider when Designing and Constructing a new paint kitchen;

- Ensuring compliance with all local and federal government Regulation’s.

- Engineering the Construction to meet load ratings and all seismic regulations

- Airflow Design and Direction is incorporated into the correct chamber design to ensure the best exhaust of all paint fumes

- Filter Design is critical to ensure the correct Layout and use of Diffusion Media to prevent foreign particles entering the airstreams

- Correct Lighting Design and Layout to ensure ample lighting for operator use

- Infinite Controls to ease use and maintenance of booth including all electrical components (Climate, Lighting, VFD’s, etc./…)

Paint Mixing Room

APPLICATIONS

BlastOne’s Paint Kitchens are developed to provide fast delivery and easy installation. Simple to operate and maintain, our Paint Mix Rooms provide a controlled area for safely mixing paint.

Air flows in through the filtered intake located in the ceiling on one end of the room. It sweeps downward through the work bay and into the exhaust chamber located at the opposite end of the booth. Filtered exhaust is drafted through the exhaust plenum and is then discharged through the exhaust stack to the outside atmosphere.

KEY FEATURES

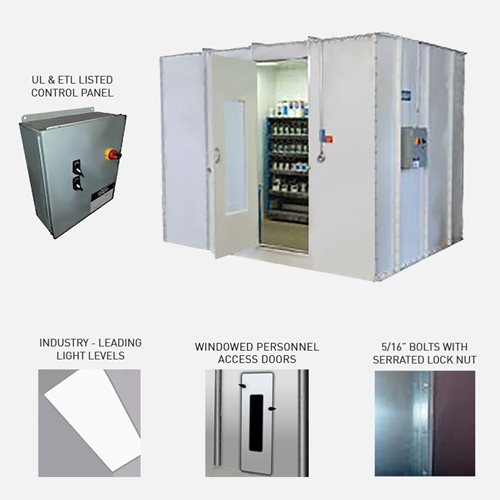

HEAVY DUTY CONSTRUCTION

Wall panels are constructed from tough 18-gauge galvanized steel while all panels and support members are precision punched for easy assembly with bolt and serrated lock nuts.

SUPERIOR DOORS

Worker entrance doors are pre-hung in a heavy gauge steel frame for easy installation.

INDUSTRY-LEADING LIGHTING

Booths receive bright, even illumination from four-tube, 48” long, 32 watt, fluorescent light fixtures. BlastOne light fixtures are ETL listed (Class 1 Division 2, Group A, B, C, D and Class 2 division 2, Group F and G.) and are supplied with a multi-voltage ballast to accept any voltage between 110vac and 277vac. Bulbs are pre-installed at the factory and tested prior to shipment.

EFFICIENT FANS & MOTORS

Quality brand name tubeaxial fans and motors.

MEETS QUALITY PERFORMANCE STANDARDS

Meets and/or exceeds with all applicable OSHA & NFPA regulations.

OPTIONS

- LED lighting

- Control panel and other electrical components can be purchased separately

- ETL listed when optional control panel is added

- Durable powder coated white option available

- Double Doors

Paint Kitchen Critical Components

THE CONSTRUCTION

Paint kitchens are built with priorities on safety, ergonomics and strength. All paint kitchens are self-supporting structures made from Steel panels or ceramic products, with an engineered structure to support the airtight environment and to meet design loads on room walls, doors and roof.

Typically the kitchen will incorporate containment below a grated floor which can be made from fiberglass and be rated up to 200 lbs/sq.ft.

SUPPLY AND EXHAUST FANS

Paint kitchen supply and exhaust fans are typical 12” (30cm) fans and are designed to meet spark resistant safety specifications. These fans have performance capacities up to 1600 cfm.

The fan on the supply side of the kitchen will have a filter to supply filtered air into the paint kitchen. Fans are selected to ensure the supply and exhaust airflow’s to create a balanced neutral air pressure within the enclosure.

SOLVENT CLEANING STATION

Having a solvent recycler in your paint kitchen is important to ensure you are not a large waste generator. These systems can range from very small table top systems to very large ‘washer’ size stations.

SINKS

The sinks are made of type 302 stainless steel with deck mounted hot and cold water supply. Sink typically will be undercoated, complete with basket strainer drain assembly.

Common Sink Dimensions

Compartments |

Width |

Length |

Depth |

|---|---|---|---|

Single |

24″ (610mm) |

20″ (500mm) |

1,148′ (350m) |

Double |

48″ (1,220mm) |

19″ (500mm) |

9.84″ (250mm) |

Consult with BlastOne

Allow BlastOne’s internal engineering team to consult with you on your Paint Kitchen or Mixing Room. This will ensure you receive the absolute best global best practices in both the design and performance of your new asset.

My Account

My Account