OVERVIEW

PROK Conveyors, a leading provider of conveyor components, faced a critical challenge in West Gosford during their blasting processes. The company’s commitment to both productivity and maintaining positive relations with their neighbors prompted them to seek an innovative solution.

CHALLENGE

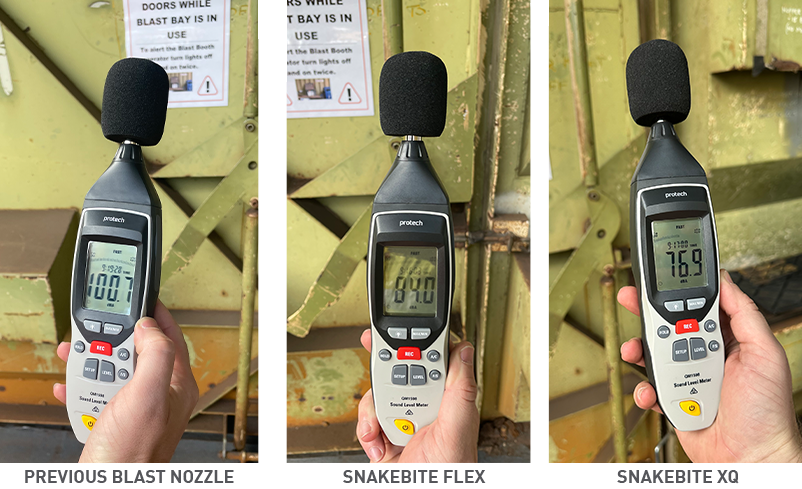

The existing process involved blasting conveyor components in an on-site chamber using GL40 & GL50 Steel Grit, resulting in noise levels reaching an intrusive 100.7dB from outside the chamber doors.

PROK Conveyors faced the dual challenge of meeting their productivity needs while addressing complaints from neighbours and workers regarding excessive noise.

SOLUTION

Upon approaching BlastOne after discovering the SnakeBite nozzles on the website, a tailored solution was proposed. BlastOne recommended the implementation of SnakeBite Flex and SnakeBite XQ nozzles. These nozzles were specifically designed to address noise concerns without compromising blasting efficiency.

RESULTS

A demonstration of the SnakeBite Flex and SnakeBite XQ nozzles showcased remarkable outcomes.

The SnakeBite Flex reduced noise levels by an impressive 16.7dB to 84dB, while the SnakeBite XQ achieved an even more substantial reduction of 23.8dB to 76.9dB. PROK Conveyors was astounded by the results, with positive feedback from both their customers and workers.

CUSTOMER TESTIMONIAL

“It [SnakeBite] exceeded our expectations and the blaster will never put it down. He even threw out his old nozzle.”

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account