Today we’re going to explain to you the blast hose manufacturing process.

It all starts right here in the Banbury. This is the Banbury that mixes all 13 ingredients that makes up the rubber compound that blast hose is made out of.

Here at BlastOne we specify that we have the highest quality materials and buy from the best vendors. This is one of the key parts that separates the BlastOne blast hose from other competitors.

What comes out of the Banbury is rubber sheets. Once the rubber sheets come out of the Banbury, it’s very important that we batch them, and every single batch we take a sample of that rubber sheet and we send it to

the lab.

There’s two main tests needed. Test with the briometer, you test the properties of that rubber puck that’s come off that sheet. Then we also do a test on abrasion resistance. First of all, you weigh the sample then you put it in the abrader and you send it 40 meters on that 60 grit sandpaper… and then you measure the weight of it after the abrasion test has been done. And you measure that in cubic millimeters of abrasion lost. So how much has been lost in that test and all of our blast hose is manufactured to a standard of… to be no more than 50 cubic mm (1.95in). Some blast hoses are made to 70 or even 100. That’s because they use lower quality products and don’t have the manufacturing process to ensure that you can always have a consistent product.

Here we are in the Calendar. You can see we have the palette of sheets here that we’re putting into the calendar to mix it one more time so it mixes it all together to make it more homogeneous and to make sure that we have a very consistent material. And we cover in a small dusting of zinc stearate to roll it out without it sticking together and causing its inconsistencies. And it’s very critical that we have to maintain tolerances to ensure that we get our high quality blast hose.

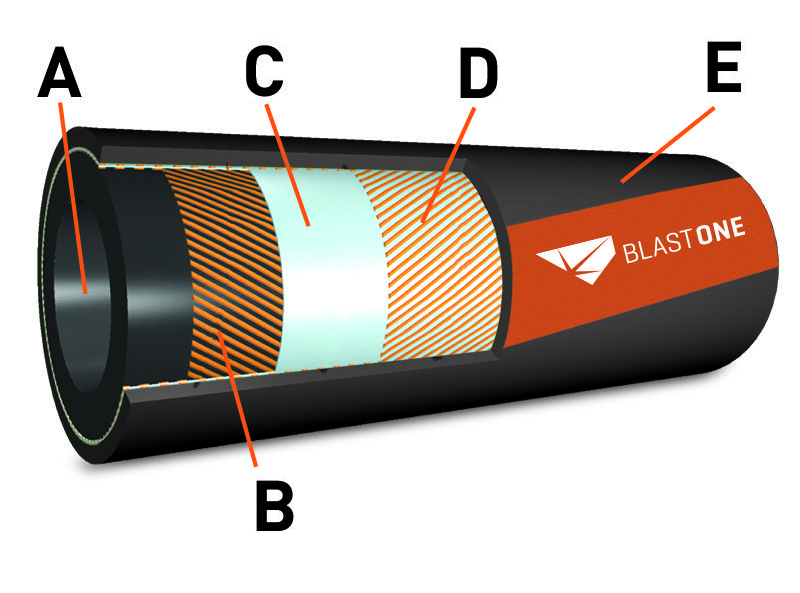

So here we have the Textile Calendar. This is where we’re putting the fly cord (textile fabric) and meshing it together with the rubber. This is the reinforced fabric that gives the pressure rating to each hose… so it gets embedded in the rubber so that we can then put that out onto the mandrel.

All blast hose is made on a Mandrel. So you have the mandrel which is a certain thickness that you want the inner diameter of the blast hose, and put them on the mandrel carriage and the carriage goes up and down putting the exact amount of rubber. One of the important parts of blast hose manufacturing process is that you add a copper wire so that it’s static dissipating. Now that we’ve done the copper wire we’re putting another layer of the textile fabric on and this is, this is very very strong, very pressure resistant and then you put on some more rubber on the outside, and the last thing you do before you put it in the vulcanizer is you wrap it in a wrapping tape which helps keep it compressed and make sure that it all vulcanizes and combines together homogeneously.

So here we are at the Vulkanizer. This is where we knot together all that products on the mandrel. We put it in there at 150 degrees Celsius (302 F) at 60 PSI and it goes in there for 70 minutes and that gives it enough time to melt together, homogenize together, and then you pull it out let it cool down and then we go take it off the mandrel. After we have come out of the vulcanator let me pull it out and we roll it up.

Welcome to the blast hose manufacturing process.

My Account

My Account