As a facilities solution provider, we often encounter industry myths regarding the practicality of installing a blasting robot. Our clients are often surprised by the truth behind costs, expertise needed, and whether it would be practical for their specialty and facility.

In this Primed Insight we’re battling 5 popular misconceptions about robotic abrasive blasting, including cost, technical expertise needed, range of applications, and facility requirements.

MYTH #1 – SHOPS WITH INCONSISTENT JOBS ARE NOT PRACTICAL FOR AUTOMATION

Having a high variation of product sizes and product flow does not automatically disqualify robotic automation. In such a situation, choosing a robot that has multiple programming options to satisfy the various products, as well as a cab for manual control is often the solution to this scenario. The robot operates off software that can be tailored for many different products, and changing between programs is easy and can be accommodated hourly if need be.

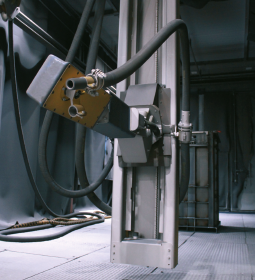

MYTH #2 – WE CURRENTLY HAVE A BLAST BOOTH THAT WAS DESIGNED FOR HUMAN LABOR SO A ROBOT PROBABLY WOULDN’T FIT

Already having a blast room is the standard scenario we encounter and places you at no immediate disadvantage. Upon completing a preliminary study of your facility’s booth, we can then determine which robot would work best for your operation.

MYTH #3 – ROBOTS MUST BE EXPENSIVE AND BEING A SMALL COMPANY WE PROBABLY CAN’T AFFORD ONE

Typically the highest cost associated with blasting is labor. The robot can effectively replace many blasters, operate 24/7 without associated benefit costs or injury potential, and only needs one person to operate. This operator can execute valuable related tasks such as prep, clean-up, etc. We typically strive to have ROI’s in 1-2 years.

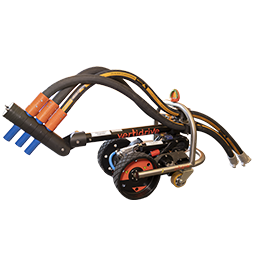

MYTH #4 – AREN’T MODIFIED WELDING OR PAINTING ROBOTS JUST AS EFFECTIVE AS A SPECIALIZED ROBOT?

Repurposing and retrofitting anything for a specialty it was not designed for will inevitably incur added costs, headaches, and unforeseen problems. Blastman robots are not standard robots, but specifically designed for one thing – abrasive blasting. There are no unforeseen problems or issues for that application.

MYTH #5 – OUR STAFF ARE BLUE COLLAR REGULAR PEOPLE. NOT TECH ENGINEERS OR PROGRAMMERS. WON’T A ROBOT REQUIRE HIRING A SPECIAL TECH TO RUN IT?

No. The best operators are ex-manual blasters. The software is easy to program and Blastman will ensure all the proper training. You will not need to hire any new IT personnel or techs to run the robot.

My Account

My Account