Abrasive Expenses Are Not Simply Confined To The Price of The Abrasive

Often, when companies are estimating their blasting costs, they consider each line-item cost independent of the others and therefore, seek to minimize each expense – believing that is the best recipe for profitability. Through this reasoning they wrongfully assume that the cheaper the abrasive – the better it is for their overall profitability.

But the blasting process is not the same as making a fruit salad whose total cost is simply the collective sum of each independent ingredient. There is a great deal of interplay between the system components on a blasting jobsite.

Understanding the Interplay of Components

Cheaper abrasive may not be as effective and thus you’ll need more of it to complete the project. Using more of it may also require additional clean-up and disposal costs. And quite frequently the cheapest abrasive will also be the dustiest, which can increase costs in the form of environmental fines or containment materials, lack of productivity due to blaster’s compromised vision, or even worse – safety mishaps that cause injury and further delays.

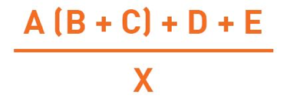

The Unites States Navy established a formula that accounts for the interplay of the blasting components and allows you to discover the total cost per square foot (or square metre) of the surface area blasted.

The formula works by calculating the blasting costs below

A = Abrasive Consumption

B = Delivered cost of abrasive

C = Disposal of abrasive

D = Labor cost

E = Equipment cost

X = Blasting Speed in square foot/hour (or square meter/hour)

Understanding the many dimensions in which your abrasive affects your total cost is critical in properly submitting a profitable bid. Cheaper is always cheaper.

My Account

My Account