Conjet robot overcomes harsh chemical environment and high risk work

OVERVIEW

Protective Coating Systems (PCS) supplies concrete maintenance, protective coatings, non-skid flooring and concrete repair services to mining, industrial and commercial clients.

PCS approached BlastOne to provide a solution for a challenging application in Bunbury, Western Australia. This involved the need to expose post-tensioning cables in concrete without damaging the cables. In order to inspect or repair post-tensioning cables, they need to be exposed, which can be a difficult and delicate process.

SOLUTION

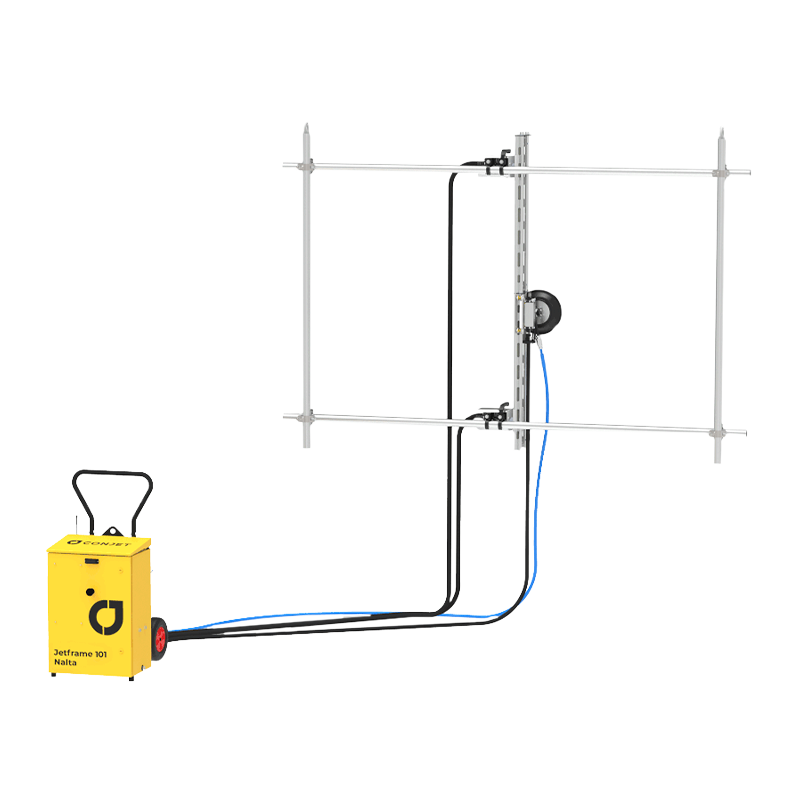

BlastOne recommended the use of a Conjet 557 concrete demolition robot in conjunction with a 1400 bar (20,000 psi) NLB Water Jet Pump which enabled the concrete to be removed to a controlled depth of 150mm around the cables.

The Conjet robot is operated remotely, which means that the operators can be positioned safely away from the work area, reducing the risk of injury or exposure to dust and debris.

The alternatives to using the robot would have been to either use percussion tools – with the likelihood of damaging the cables, or to use a hand-held water jet lance – putting the operator and environment at risk from the high-pressure water jet and flying debris.

My Account

My Account