Holiday Detector Kit 30KV with band brush probe

IMAGES & VIDEO

Holiday Detector Kit 30KV with band brush probe

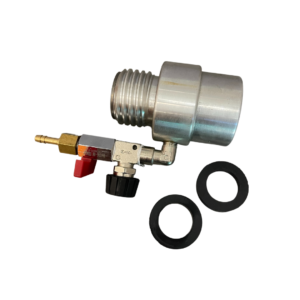

PT Holiday Detector Kit 0-30kV, c/w band brush probe

- For use with coatings up to 8,000 microns.

- Resolution of 0.1kV

Read More

Holiday Detector Kit 30KV with band brush probe

SKU: INDPT30KWeb price i

Please sign in to your account to see your pricing, which may be different from the price displayed.

$6,303.30

$5,730.27 (excludes GST)

Ship to

Holiday Detector Kit 30KV with band brush probe

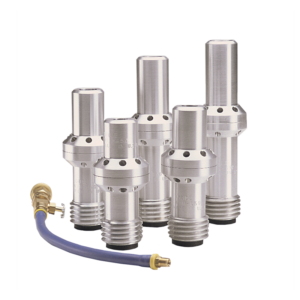

Sku: INDPT30K

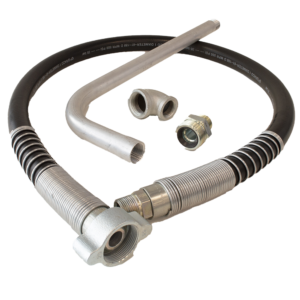

The BlastOne PT Holiday Detector is used for detecting porosity, pinholes and flaws in coatings on conductive substrates. Pinholes will eventually lead to premature coating failure. Coatings provide an effective safeguard against corrosion, so it is critical that any pinholes are detected at the earliest possible stage after coating cure. The BlastOne PT Holiday Detector is supplied in an industrial Carry Case, with 0-30kV High Voltage Handle, Band Brush Probe, 10m Earth Cable and Carry Bag. Calibration Certificate is available as option. The PT Holiday Detector is compliant to ISO 29601, ISO 2746, NACE SP0274, NACE SP0188 and NACE SP0490. Also known as Holiday Tester, Pinhole Detector, Porosity Detector, Porosity Tester and Spark Tester. What is the difference between a holiday detector and a porosity detector? A holiday detector and a proximity detector are in essence the same thing. An electrical current is run over the painted/coated steel surface and in the event of porosity or pinhole in the coating (also known as a holiday) the current short-circuits to earth and creates an alarm. With high-voltage holiday detectors this can create a spark – hence the name spark tester. BlastOne has complete range of coating inspection instrumentation, such as digital coating thickness gauge, CTG, ferrous or nonferrous, surface profile meters / surface profile measuring device, testex tape, dew point meters, and magnetic surface thermometers. There are many spark tester manufacturers which make different configurations of spark tester/holiday detectors – depending on the application and the complexity of the surface that requires testing for porosity in the paint coating High-voltage spark tester is come with different width bristle brushes or rolling spring probes, which can be used on pipelines Low-voltage sponge detectors and sponge holiday detectors are also available Paint inspectors should use caution when using high voltage porosity detectors high-voltage holiday detector It is important that 100% of the coated surface is tested for pinholes using a spark tester. Where ever a pinhole is located, a repair must be conducted in the paint coating – To ensure long coating life and and low maintenance Most Holiday Detectors have Regulated direct current pulse voltage outputs What voltage should I use for holiday detection/pinhole detection on my paint coating? To determine which voltage I need to use on my spark tester, it is important to refer to the paint coating spec sheet and the relevant standards applicable to high-voltage porosity detection My Account

My Account