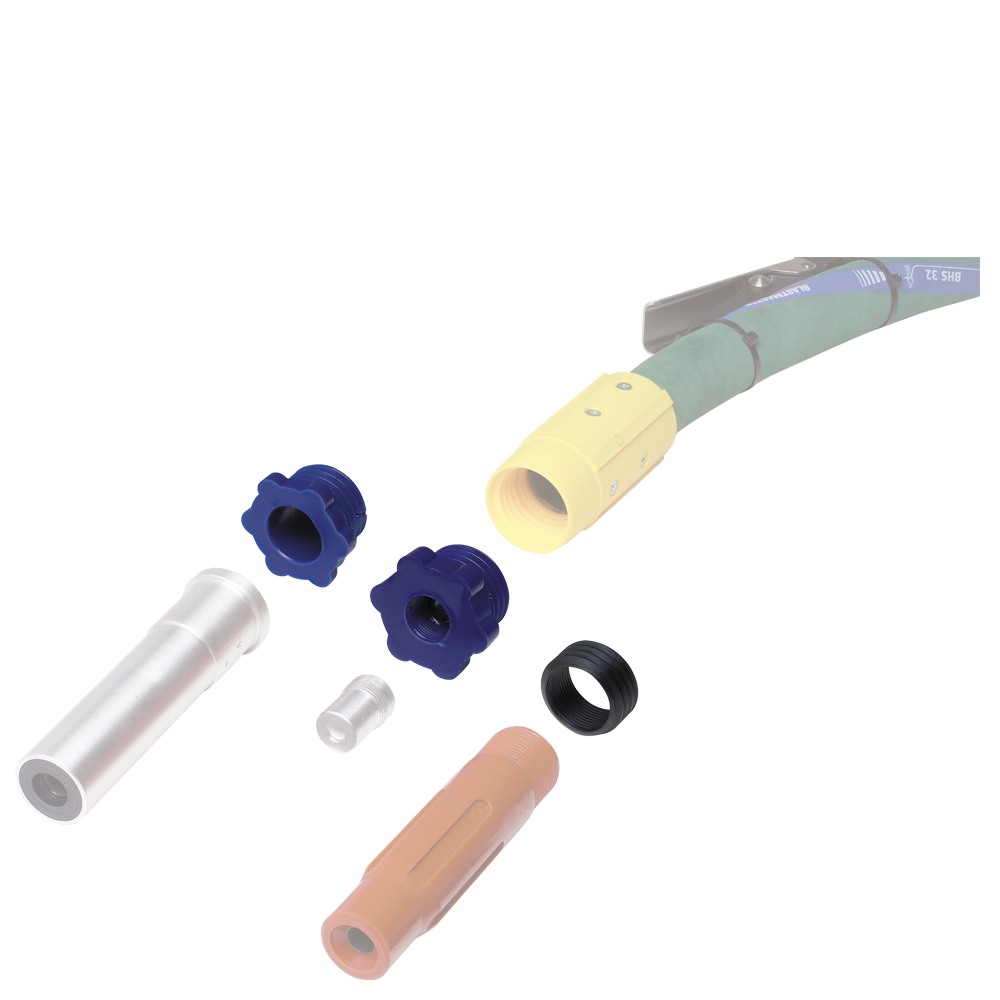

Predominantly in the industrial sandblasting market, the # 6 nozzle is the most common followed closely by a # 7. This is 6/16th or 3/8th and 7/16th size. When choosing a nozzle for sandblasting it is important to maintain to get the right size, you can maintain 100 psi at the nozzle. This means you base the size nozzle on your compressor and the work you have to do. To maintain 100 psi is very simple to calculate, cfm requirements and your air compressor. For example, there’s a table included on this page, which gives you the amount of cfm you need for each nozzle size. The other implication on nozzle size is how big of a blast pattern you want and how much you have to do. A smaller blast nozzle will have a smaller pattern and blast slower. So, if you have production and you have the right sized compressor, go as large as you can. The largest nozzle as a man can hold.

My Account

My Account